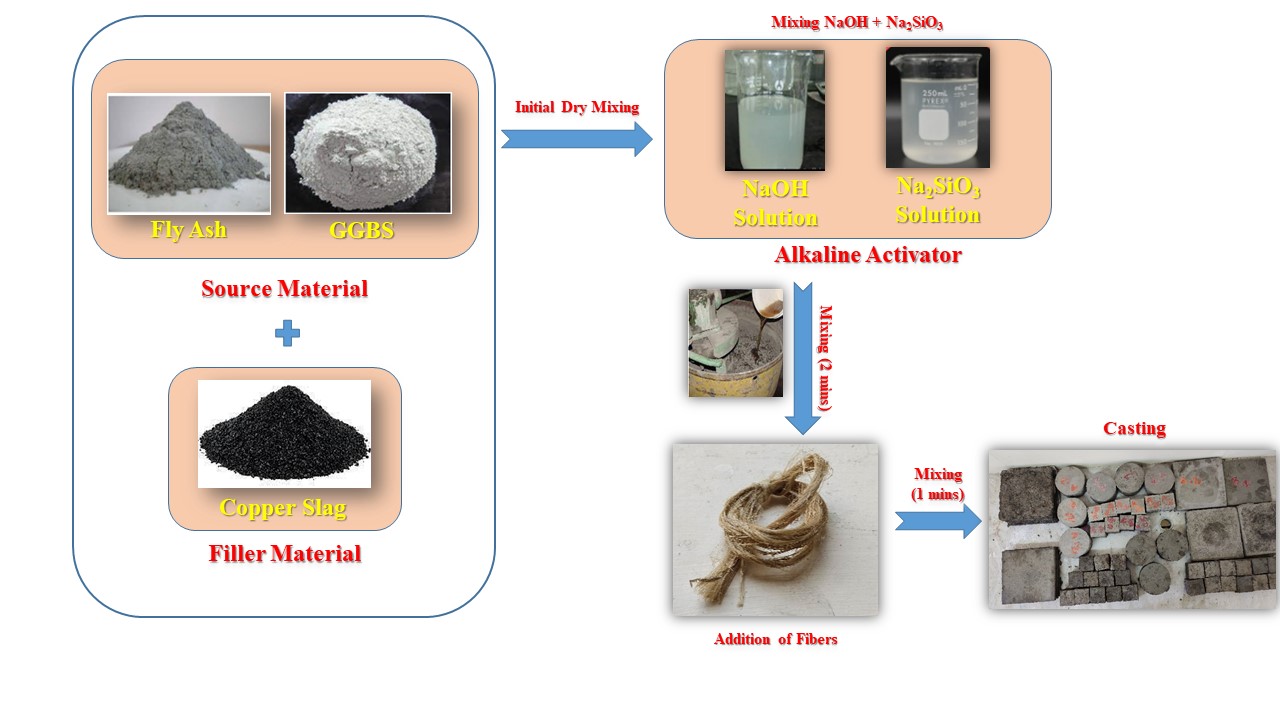

Efforts have been put forth in the past to develop sustainable construction material by reducing the use of cement and river sand which can directly provide a positive impact on our ecosystem. In this work, an attempt is made to develop a sustainable a geopolymer composites with the use of fly ash (FA) and Ground Granulated Blast Furnace Slag (GGBS) as precursor binder and copper slag as a complete replacement for conventional fine aggregate. In addition, discrete natural fiber such as flax is added to the composite matrix to provide sufficient tensile strength and better bonding capabilities. The fiber volume fractions were fixed as 0.25%, 0.50%, and 0.75% to the total volume of the composite matrix. All the cast specimens undergo an ambient curing process to complete the polymerization mechanism for strength gain. Results reveal that the geopolymer composite mix with 0.25% of flax fiber was found to outperform the other mixes based on the enhancement in mechanical strengths. Moreover, the addition of fibers of more than 0.5% results in the marginal reduction of compression and flexural tests which could be due to the improper fiber dispersion or fiber bundling at specific locations leading to the absence of required fibers at the fracture plane. In addition to the mechanical tests, a detailed micro-structural analysis was performed using the scanning electron microscopy (SEM) to understand the interface between the fiber and the matrix.

Total file downloads: 25