- Cite article

- Download PDF

- Share article

- 19 Downloads

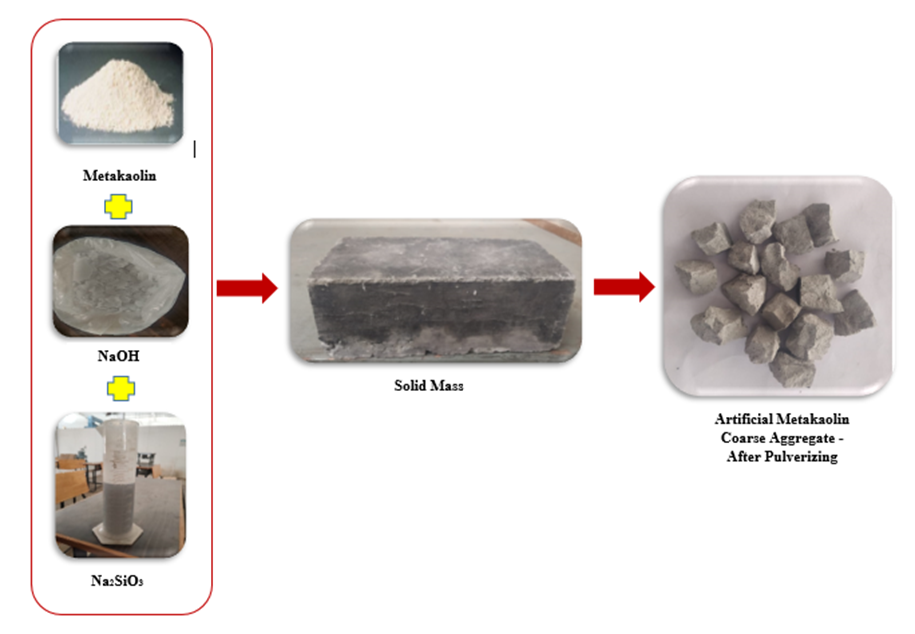

This study presents a unique methodology for investigating the properties of Metakaolin Coarse Aggregates (MCA). The NaOH ratios were varied as 8M, 10M, 12M, and 14M, while the NaOH to Na2SiO3 ratio was maintained at 0.5 entire study. The liquid-to-binder (L/B) ratios set at 0.3, 0.35, and 0.4. Testing was conducted on the MCA to determine its physical and mechanical properties, comparing them with those of Natural Coarse Aggregate (NCA). Notably, the 8M mix with a 0.4 L/B ratio was found to be economical for producing MCA and was selected for further research. This chosen mix was then employed to prepare geopolymer concrete with 50% MK and 50% PA, with L/B ratios set at 0.4, 0.45, and 0.5. The NaOH ratio and Na2SiO3 to NaOH ratio were maintained at a constant 8M and 2, respectively. Mechanical and durability properties were compared between Geopolymer concrete with NCA and Geopolymer concrete with MCA. The test results demonstrate that MCA in geopolymer concrete can effectively replace NCA in geopolymer concrete, making it a viable option for structural members. Additionally, microstructural characterization was performed on Geopolymer concrete with MCA mixes with varying L/B ratios of 0.4, 0.45, and 0.5, at 28 days. The study specifically focuses on the Interfacial Transition Zone (ITZ) between MCA and geopolymer paste, revealing an improvement in ITZ and microstructure in the GMCA sample with a 0.4 L/B ratio compared to other mixes.