- Cite article

- Download PDF

- Share article

- 32 Downloads

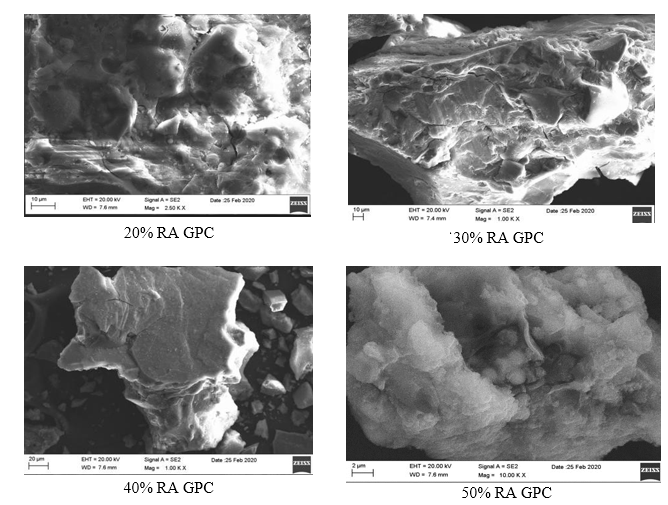

Industrial by-products such as cementitious materials or aggregates have the potential to mitigate the adverse environmental effects associated with traditional cement manufacture. Geopolymer Concrete (GPC) is more eco-friendly than conventional concrete because it does not require cement. GPC with Recycled concrete aggregates (RCA), Ground granulated blast furnace slag (GGBS), and Fly Ash (FA) reduce raw material use and create sustainable infrastructure. GPC compounds increase workability, slump value above standard concrete, and reduce the amount of water usage. The study examines GPC mechanical properties, durability, and environmental properties with different RCA content. The M30 concrete mix design is established by trial and error utilizing a 0.45 water/binder ratio. GPC with 0%, 10%, 20%, 30%, 40%, and 50% recycled coarse aggregate replaced natural aggregate(NA) by mass. GPC with 50% GGBS provides an early strength of 96% of normal compressive strength on day seven. The compressive, split tension, and flexural strengths exhibit significant improvement with up to a 40% substitution of NA with RA. These results highlight GPC's potential as a sustainable alternative in the construction sector.