- Cite article

- Download PDF

- Share article

- 11 Downloads

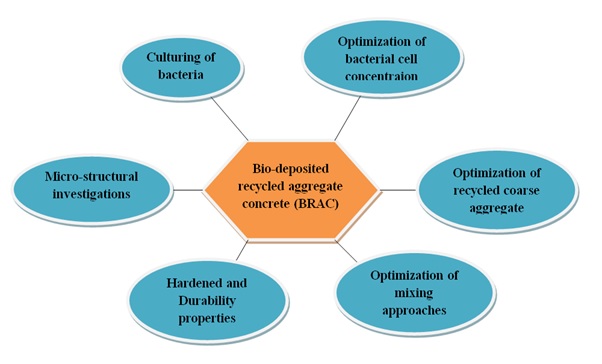

Excessive consumption of natural resources for concrete production results in the diminution of conventional resources, leading to the scarcity of construction materials. Perhaps, the dumping of construction wastes increases the municipal wastes ensuing in disposal problems. The dumped construction wastes act as a hazard and disturb the integrity of the environment. Nevertheless, the requirement for aggregates in the construction sector increases, hastily alarming the researchers in their search of sustainable alternative materials. The recycling of construction waste to produce recycled coarse aggregate (RCA) as a suitable alternative to natural coarse aggregates (NCA) conserves natural resources and promotes sustainability in construction. However, the quality of recycled coarse aggregate was inferior compared to natural coarse aggregates due to the adherence of mortar. This paper investigates the sustainable use of Bacillus subtilis with different concentrations to enhance the quality of RCA. The concrete mixes manufactured with optimized BRCA were tested for their mechanical and durability properties. It could be observed that the strength of BRAC was enhanced by 12.63% relative to NAC, and the durability properties such as water absorption, chloride penetration and carbonation of BRAC were reduced by 18.53%, 16.52% and 20% relative to RAC. Microstructural studies through SEM and XRD revealed the deposition of CaCO3 on the micro-pores of RCA, and that improves the properties of the concrete.