- Cite article

- Download PDF

- Share article

- 13 Downloads

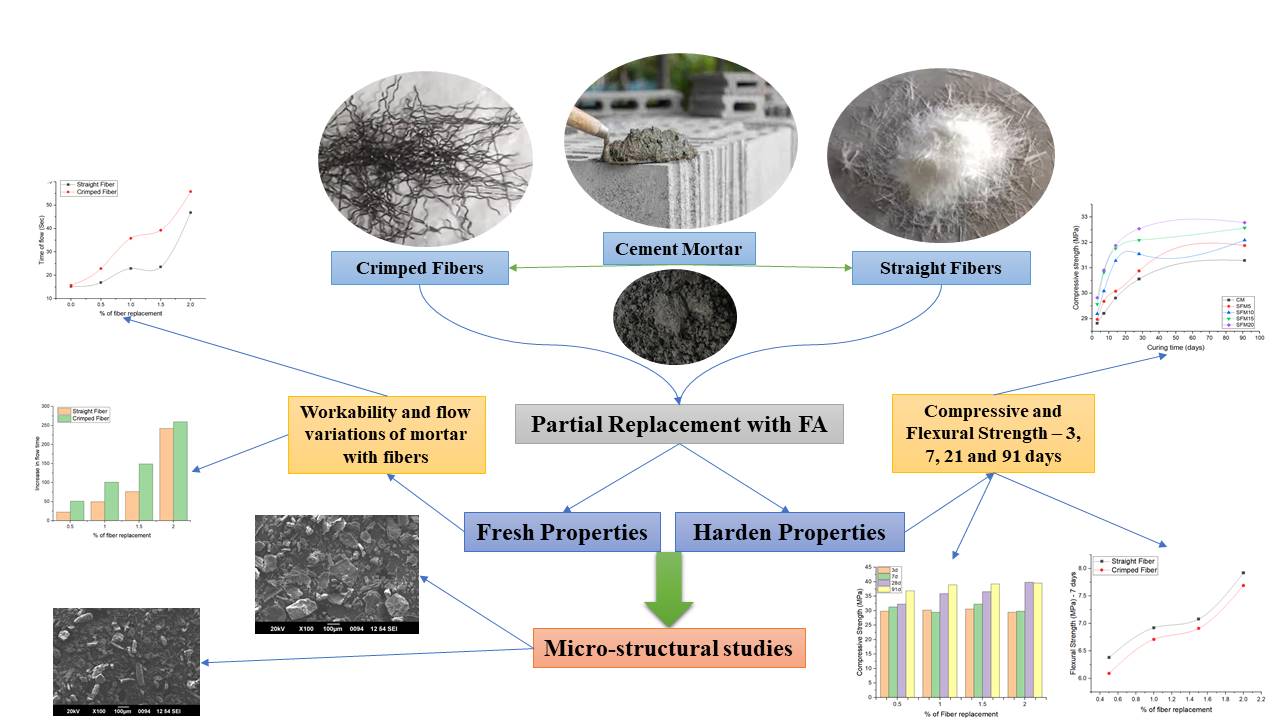

The primary goal of the research was to determine how recycled plastic fiber's shape affected the functionality of mortar made from naturally occurring limestone residue. The identical length (20 ± 2 mm) and diameter (0.45 ± 0.07 mm) of two types of recycled fibers, straight and crimped, were employed. The fibers used for this study were taken in four different ratios 0.5%, 1%, 1,5%, and 2%. Compared to the crimped fibers, the straight fibers with concrete mix have high compressive and flexural strengths. i.e., 37.52 Mpa and 9.78 Mpa of compressive and flexural strength were observed for crumped fibers lower than the straight fibers (39.73 MPa and 10.48 Mpa) mixed with concrete mix. The results reveal that the geometry of the recycled plastic fibers is a key factor affecting the performance of the limestone residue mortar. The findings show that a restricted dose of 1% and 0.5% of the recycled plastic fiber is required to produce a workable mortar for both straight and crimped fibers. Incorporating recycled plastic fibers has been demonstrated to enhance the flexural and compressive properties of limestone residue mortar; nevertheless, the strength values of straight fiber mortar (SFM) are greater than those of crimped fiber mortar (CFM). The microstructure investigation validates the fiber mortar's excellent performance.