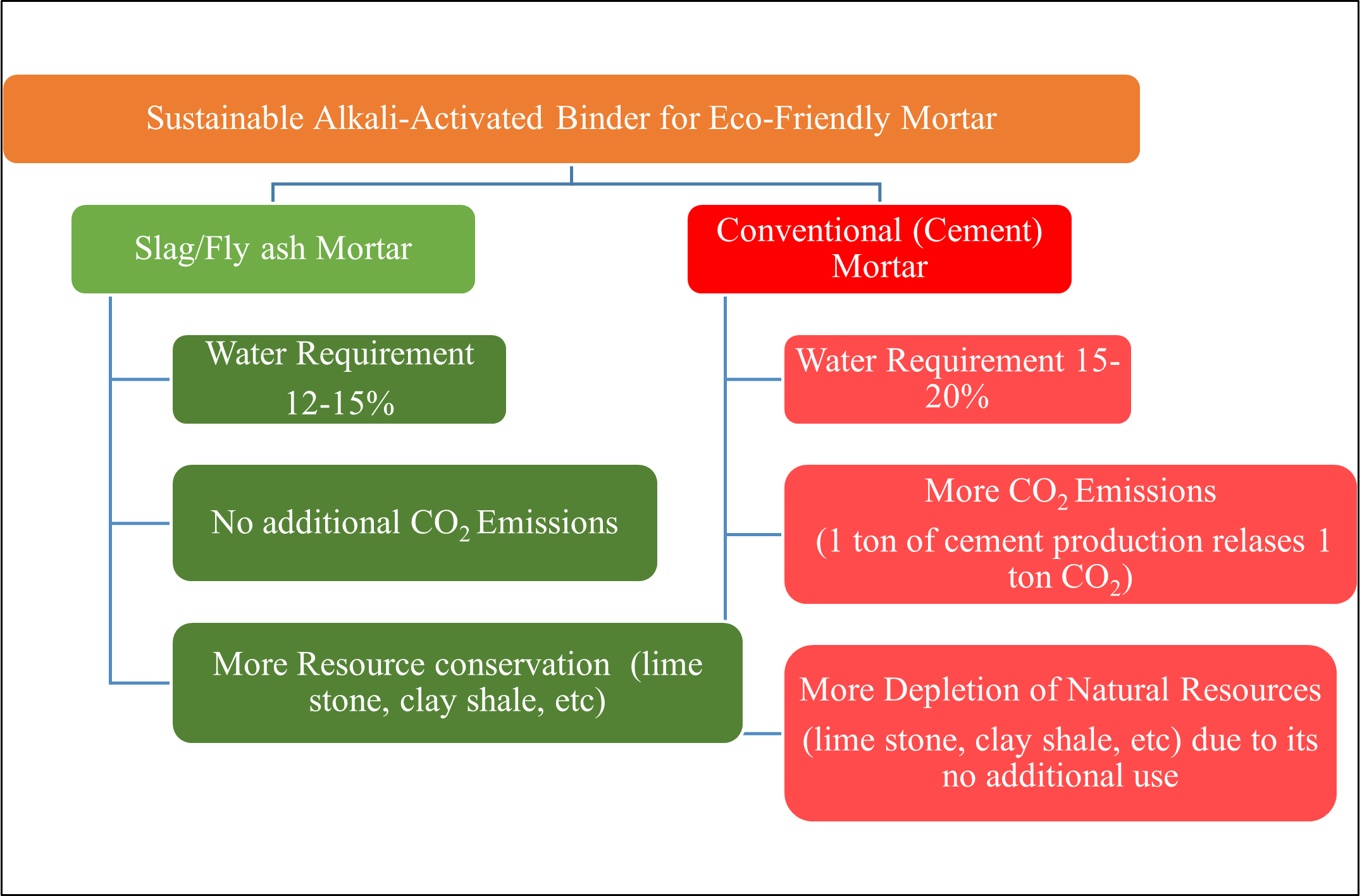

A dry mix (solution-free) alkali-activated slag (a primary cementitious material) and/or fly ash based binder composition is developed that can be cast in-site and consequently cured at ambient temperature. Mortar specimens were cast by mixing slag and or fly ash, river sand, powder form alkaline activators (NaOH 14M, varying solids percentage of Na2SiO3) and water were thoroughly mixed in fabricated equipment. The dry density (28 days) of all specimens showed greater than 2200 kg/m3. The compressive strength (28 days) of all mixes was resulted in higher than 40 N/mm2. Among all the four mixes, a mix F103 with 90% slag, 10% fly ash, 30% Na2SiO3 and 14M NaOH at 3, 7 and 28 days curing showed overall higher compressive strength. It is due to fewer solids content of Na2SiO3. The experimental results indicated that solution free studied binder composite can be developed under ambient conditions eliminating other curing types without compromising in the strength. The studied sustainable mixes require only 12-15 percent water which is less compared to regular used mixes. Thus reduced water quantities can be achieved thereby protects the reduction in volume of water bodies, environment hazards, reduces CO2 emissions due to use of industrial by-products as main binders.

Total file downloads: 32