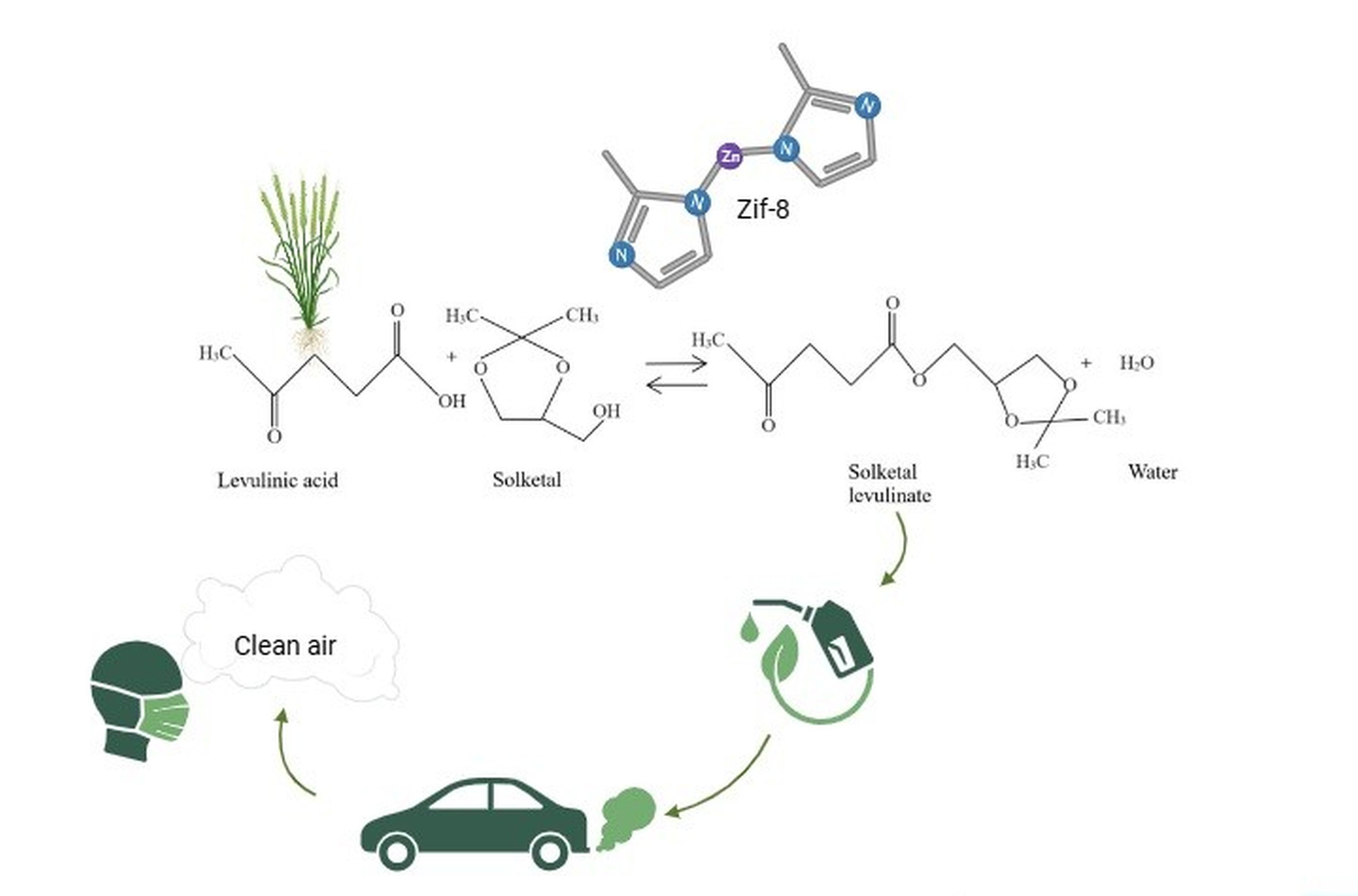

Solketal levulinate (SoLE), a potential fuel additive that can improve the physicochemical properties of the fuel, was produced by the developed catalytic membrane from solketal and levulinic acid. The catalytic membrane was prepared in film form as a metal-organic framework of ZIF-8 supported on a sulfosuccinic acid-loaded hydrophilic polyvinyl alcohol polymer. Removing by-product water from the reaction medium with the sorption of the highly hydrophilic membrane contributed to the conversion. PVA/SSA and PVA/SSA/ZIF-8 membranes were analyzed by FTIR and TGA. ZIF-8 was photographed and analyzed by SEM and XRD, respectively. Higher water affinity of the functional catalytic membranes was calculated by swelling degree and interaction parameter calculations. SoLE synthesis was conducted in the batch reactor under mild conditions. The parameters such as catalyst amount, temperature, solketal/levulinic acid initial molar ratio (M), and reaction time, were investigated. The PVA/SSA catalytic membrane showed a maximum reaction conversion of 97.65% with 105°C, 9 mmol SSA, and an M:6/1 ratio for 6 h. For the PVA/SSA/ZIF-8 catalytic membrane, maximum reaction conversion of 96.81% was obtained at 105°C, with an M:6/1 ratio and 9 mmol SSA for 4 hours. ZIF-8 reduced the reaction time and contributed to the system in terms of efficient energy use.

Total file downloads: 5