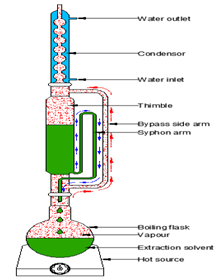

A feasible alternative fuel for diesel engines in recent days is biodiesel, which can be produced from both edible and inedible feedstock. When considering the economic and environmental aspects, there is a considerable academic interest among researchers in the transesterification of non-edible oils to yield valuable Biodiesel, as compared to biodiesel production from edible oils. Prosopis juliflora oil was extracted using the solvent extraction technique. By using a two-step acid esterification method, the FFA acid value was reduced less than 1%. The acid value underwent a two-step reduction, initially decreasing from 44 KOH/gm to 8.6 mg KOH/gm, and subsequently reaching 2.7 mg KOH/gm. The implementation of the above procedure can effectively mitigate significant problems in diesel engines when using high viscous non-edible oils. The primary objectives of this research were to maximize the biodiesel output and simultaneously minimize the acid value. Response Surface Methodology (RSM) was employed in the current investigation to optimize different parameters. D-optimal design technique in Response Surface Methodology (RSM), was used for analyzing the methanol/oil volume ratio (factor A), reaction temperature (factor B), and reaction time (factor C) as process variables. The focus of the analysis was on the percentage of acid value (Y).

Total file downloads: 5