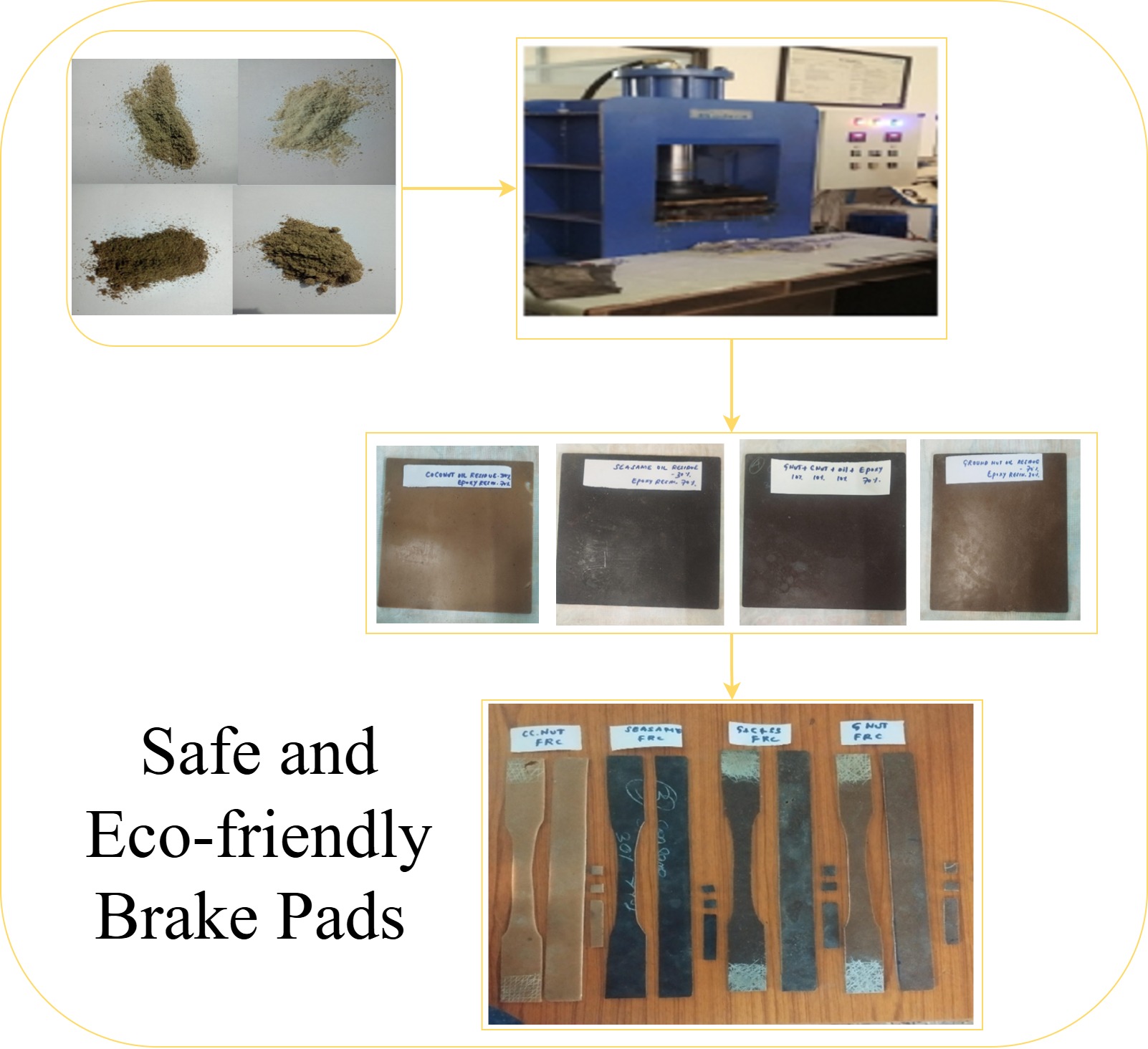

Brake pads are the major automotive component that ensures safe braking by controlling the speed of vehicles. Conventional brake pads contain harmful materials like asbestos and heavy metals, adversely affecting human health and the environment. Conventionally, there is an increasing demand for eco-friendly alternatives to maintain or improve the performance of brake pads with reduced environmental impact. This study aimed to develop eco-friendly brake pads from four oil residue materials: coconut, groundnut, and sesame. The performance of these residues combined with an epoxy resin matrix with a reinforcement ratio of 30:70 is evaluated. Various mechanical properties like tensile, impact, hardness, flexural strength, wear test, chemical properties like FTIR, water absorption, thermal analysis as TGA, microstructure test of SEM & EDS, and biodegradation test with bacteria as Acinetobacter baumannii compost and its morphological surface are examined for assessing the environmental impact of these materials. The results demonstrated notable improvements with mechanical properties and biodegradation analysis, confirming these materials' environmental sustainability and highlighting their potential to be utilized as an effective reinforcement in brake pad applications. Flexural strength improved by 15-20%, with values of about 42.5 MPa, while tensile strength rose by around 18-22%, reaching up to 28.6 MPa. The impact strength was increased by 25-30%, and energy absorption reached 4.9 kJ/m², higher than the 3.7 kJ/m² achieved by conventional alternatives. Superior abrasion performance was shown by an 8-10% rise in Shore D hardness, which reached values of 79-81, and an improvement in wear resistance, with a specific wear ratio decrease of 12-16%.

Total file downloads: 24