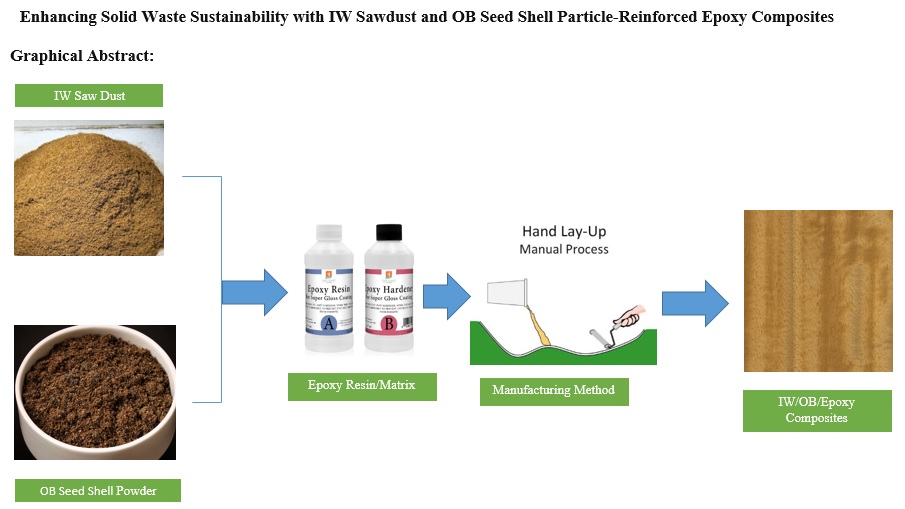

Bio-composite materials are gaining traction in various industries as sustainable alternatives to synthetic fiber-reinforced composites. This study investigated the impact of fine powders loading on the tensile, transverse, and compressive characteristics of hybrid composites composed of Iroko wooden sawdust and oil bean pod shells. Employing a 1:1 ratio of sawdust and oil bean pod shell particles as fillers, a hybrid composite configuration was formulated. Different reinforcement levels, specifically 20%, 30%, 40%, 50%, and 60%, were employed. The manufactured composites underwent rigorous ASTM testing, and the results revealed that filler reinforcement significantly influenced the tensile, compressive, and transverse properties of the composite material. While the percentage of elongation at fracture increased up to 40% before reaching a decline, the tensile strength, transverse rupture strength, transverse modulus, and compressive strength consistently improved until a 50% filler loading. The findings from this study underscore the potential of composite materials incorporating Iroko wood, oil bean pods, and epoxy as effective alternatives to conventional wood-based materials in various applications, thus contributing to sustainable solid waste management.

Total file downloads: 14