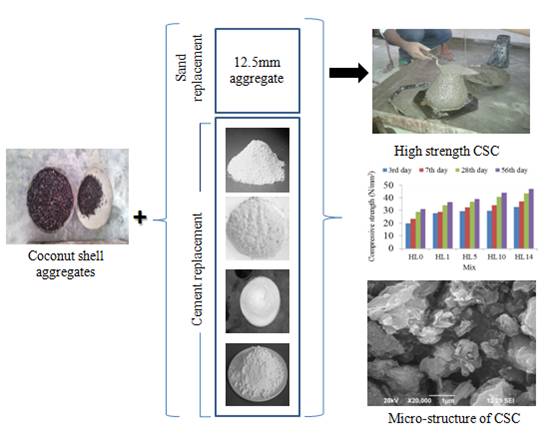

In this investigation, coconut shell, a lightweight agricultural waste, is used to completely replace coarse material. Based on previous findings, it is suggested that coconut shell be used as coarse aggregate in structural lightweight concrete. Therefore, the purpose of the study was to develop coconut shell concrete with high strength by varying the size of coconut shell aggregates, adding a higher quantity of cement, adjusting the water content, utilizing metakaolin, nanosilica, limestone powder and silica fume as cement substitutes, and using coarser fine aggregate. Trial and error method was utilised to find the appropriate ingredient ratios. Fifteen different mixes were used to optimize the strength of coconut shell concrete. Slump, ultrasonic pulse velocity, density (fresh, demoulded and air-dry) and compressive strength (3, 7, 28, and 56 days) were tested in each mix. Coarser fine aggregate improved the performance of coconut shell concrete. Density ranged from 1980 to 1996 kg/m3 for this lightweight structural concrete made from coconut shells. In just 7 days, 80-93% of 28-day strength was achieved. The small size of the coconut shell aggregates allowed for an improved paste-aggregate bond, which increased the compressive strength. By using a coarser fine aggregate in coconut shell concrete, the 28-day compressive strength of the resulting concrete was 43.6 N/mm2, above the minimum requirement for high-strength lightweight concrete.

Total file downloads: 104