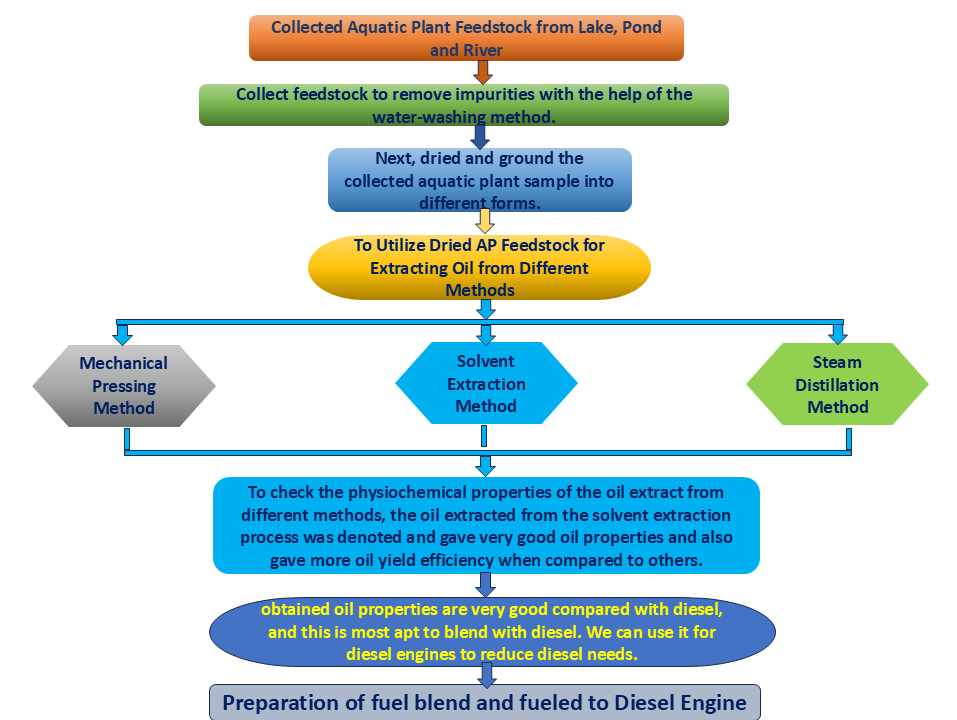

Aquatic plants are the one of largest and fast-growing biomass resources that have substantial potential for diesel production. One of these, Hydrilla verticillata, is a submersed aquatic plant that can prosper in warm lakes and rivers at depths of several meters and was therefore studied as a potentially new feedstock for biofuel. This study demonstrates “third-generation biofuel”, for the first time, the viability of Hydrilla-based biofuel as a sustainable third-generation feedstock. The research was on oil extracted from Hydrilla using various methods with same weight of feedstock for three different methods: steam distillation, Soxhlet extraction and mechanical press. Yields of extraction were greatly affected by the particulate size and biomass moisture content. A maximum yield of 13% oil was obtained by mechanical pressing, suitable for biodiesel production, under the optimized conditions in case of steam distillation, we could get about 34.2% oil (the similar quantity as in crushed seed). Maximum yield of 63.8% was observed in the case of solvent extraction with fully dried aquatic plant feedstock using n-hexane solvents and finely powdered biomass gave a low viscous oil suitable for fuel applications by production method itself as solvent extraction, we’ll all levels of properties results very closer to diesel fuel compared to other two process so that obtained oil from solvent extractions process has been taken for further blend with diesel blending and also fuelling to CI engine level. Physical and chemical properties analysis of the Hydrilla oil revealed similar characteristics with a relatively acceptable range in comparison to diesel, and it could be utilized as an engine fuel. Performance was evaluated by using Hydrilla biofuel blends and diesel in a single cylinder, four stroke Compression Ignition engine. Engine trials showed that a blend of 20% biofuel and 80% diesel felt similar to neat diesel and better compared with already existing aquatic plant of (water hyacinth, Spirogyra) in terms of the key findings from BTE investigation using the Hydrilla B20 blend reveals that it complies up to 31.13% of normal diesel fuel and a small drop of 1.70%, in cylinder pressure was reduced, the energy released during power stroke is 0.87 percent lower and heat release rate of the engine was decreased 2.02% when compared to standard diesel. Beside emission part CO 15% and HC emission 1.38% increased due to the slightly improper combustion, NOX and CO2 emissions are decreased due to low temperature occurred in combustion chamber. These findings demonstrate the potential of Hydrilla-based biofuel as an ecofriendly partial replacement to diesel with greater versatility and lesser dependence on fossil fuels in favour of cleaner energy sources.

Total file downloads: 2