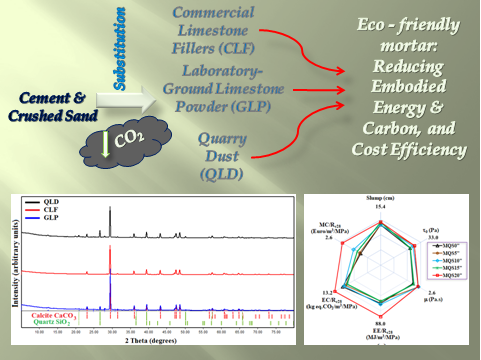

This study evaluates the eco-efficiency of mortars incorporating three types of limestone fillers (LF): quarry limestone dust (QLD), commercial limestone filler (CLF), and laboratory-ground limestone powder (GLP). Sustainability metrics considered include embodied energy (EE), embodied carbon (EC), material cost, which were normalized to compressive strength and rheological performance, as well as particulate matter emissions (TSP, PM10, PM2.5). Results show that GLP, owing to its high purity confirmed by FTIR and XRD, achieves the best eco-efficiency, with lower EE, EC, and cost per MPa compared to QLD and CLF. QLD substitution up to 20% in crushed sand (CS) mixtures progressively reduced particulate emissions, reflecting its by-product status with no additional processing. While PM2.5 reductions were modest, notable decreases in PM10 and TSP highlight the mitigation of coarse dust emissions from CS processing. Even with the added cost of Sp, incorporating up to 15 wt% QLD while maintaining constant slump remains a balanced strategy. The eco-indices further confirm that optimal performance is obtained around 10–15% QLD substitution, where both environmental and mechanical efficiencies converge. Overall, the findings underscore that filler selection and treatment should be guided by both technical performance and environmental outcomes, aligning material efficiency with improved air quality indicators.

Total file downloads: 15