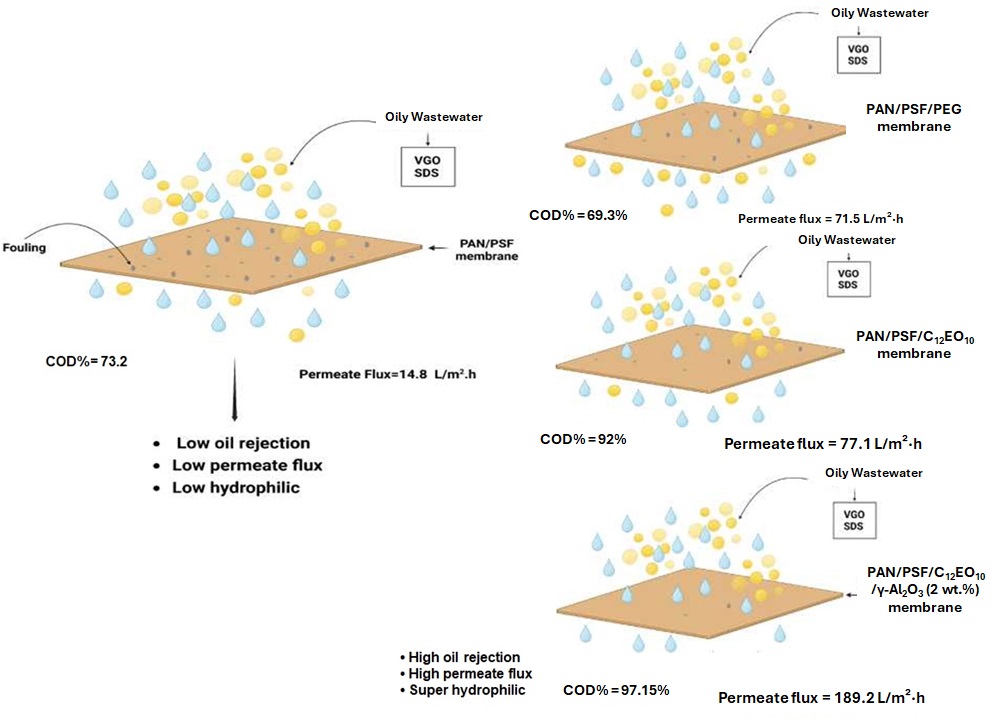

The polyacrylonitrile (PAN)/polysulfone (PSF) blended polymer membranes were modified by decaethylene glycol monododecyl ether (C12EO10) as a non-ionic surfactant. Polymeric solutions containing 17 wt.% of both PAN and PSF with a ratio of 80/20, and C12EO10 with a mass concentration of 6 wt.% and aluminium oxide (Al2O3) nanoparticles with varying concentrations (1, 2, and 3 wt.%) were prepared. Adding 6 wt.% of C12EO10 to the casting solution formed a membrane with distinguished hydrophilicity and fouling resistance, higher porosity, appreciable permeate flux (77.1 L/m2.h), and distinct vacuum gas oil rejection (92%) in comparison with the pure PAN ultrafiltration membrane. Further improvement for the PAN/PSF blend membrane using 2 wt.% of γ-Al2O3 in the presence of 6 wt.% of C12EO10 (PPCA-6-2γ membrane) produced an excellent permeate flux of 189.2 L/m²·h, favorable hydrophilicity with a contact angle of 26.55°, and an optimistic COD removal%, expressing the VGO rejection, of 97.15%. The PPCA-6-2γ membrane revealed acceptable separation performance up to four cycles of filtration and exhibited enhanced antifouling properties with an FRR% of 95.4%. The fouling mechanism that determines the flux reduction during crossflow ultrafiltration by the PPCA-6-2γ membrane was studied using the Hermia models. The cake layer formation model provided the best match for the experimental behavior when analyzing the flux reduction with time for the PPCA-6-2γ membrane. The fabrication cost was determined for PPCA-6-2γ membrane to be $1.67/20 g, respectively. So, the local manufacturing costs of the PPCA-6-2γ membrane did not surpass 90 $/m2 of the membrane.

Total file downloads: 13