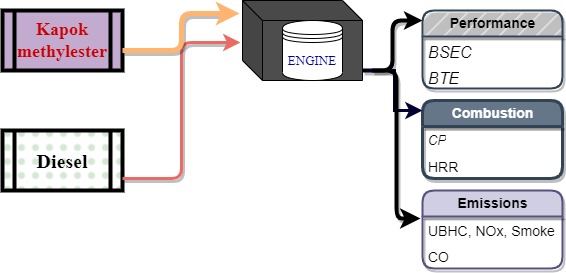

Energy is essential but associated with global greenhouse emissions. Therefore, clean and renewable energy is important for future development. To meet this demand, kapok oil methyl ester (KOME) was made from the kapok raw oil through the transesterification method. KOME was then combined with diesel in the ratios of 10%, 20%, and 30% (v/v%) to form KOME10, KOME20, and KOME30 mixtures. The combustion and emissions outcomes of KOME blends were studied at a stationary DI engine under different loads and modified common rail direct injection (CRDI) mode at 400 bar injection pressure, partial load, and CR of 19:1, 20:1, and 21:1. The combustion analysis of blends like maximum pressure (Pmax) and net heat release rate (HRRmax) were observe lesser than diesel at stationary mode, whereas they increased by 13–15% and 16–32% in CRDI mode, respectively. Exhaust from engine such as carbon dioxide, hydrocarbons, and smoke were decreased, but nitric oxide increased about 0.7–1.5% and 1.3–8% for stationary and CRDI modes, respectively, as compared to diesel. This concludes that KOME might be a suitable substitute to diesel fuel for non-road DI engine applications.

Total file downloads: 14