- Cite article

- Download PDF

- Share article

- 13 Downloads

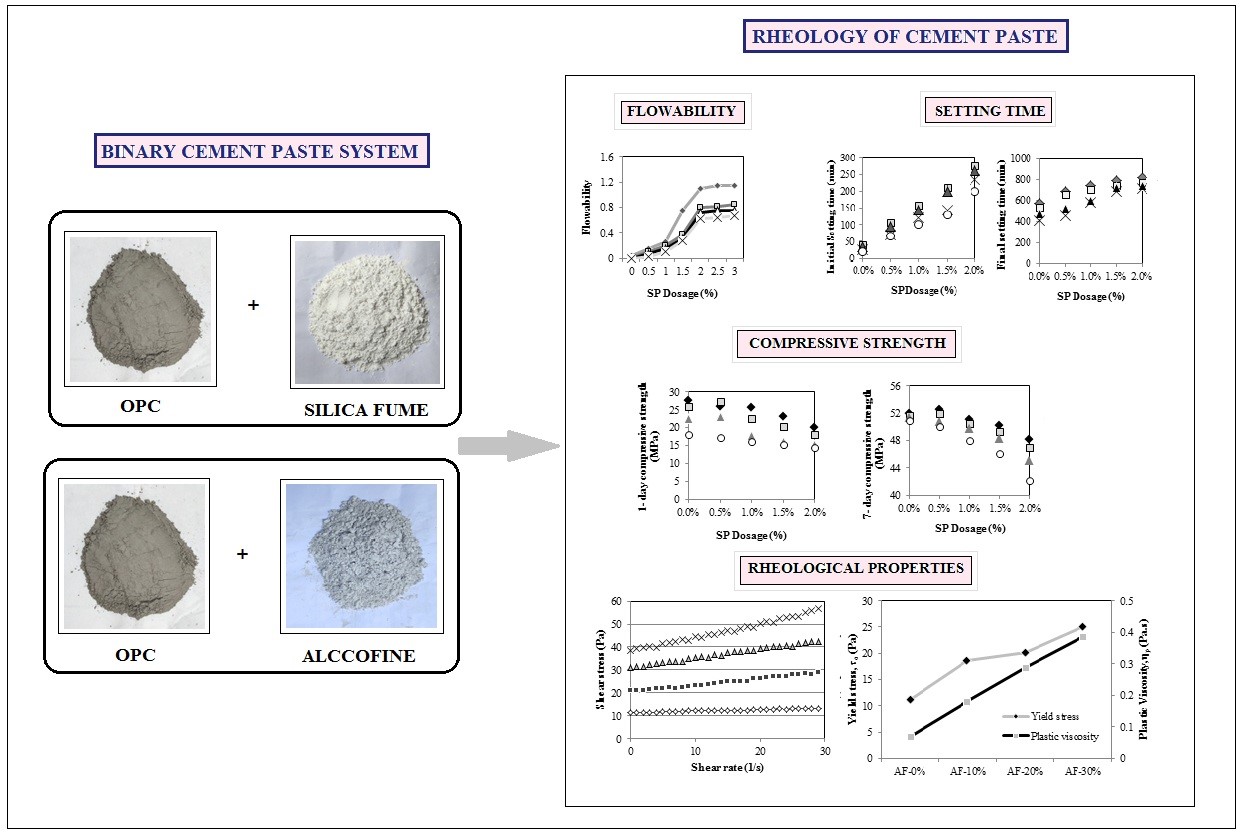

The flow properties of the binary cement paste system added with supplementary cementitious materials, effect of polycarboxylate based superplasticizer dosage and their influence on the yield stress and the plastic viscosity were studied. The cementitious materials under the study are silica fume and alccofine. Both the plain cement and the binary cement paste system were considered and tested. A comparative study between the plain cement paste without any additions, silica fume blended cement paste and alccofine blended cement paste was performed. The addition of cementitious materials varies in the range 10%, 20% and 30% and the superplasticizer dosage varies in the range 0.5%, 1.0%, 1.5%, 2%, 2.5% and 3% in the mini-slump flow test and the saturation point was determined to be 2% in both the cases of silica fume and alccofine. The setting time and compressive strength testing on the cement paste considered the superplasticizer dosage up to saturation point. The flow characteristics are broadly the same among the binary paste systems. The setting time results indicated the increase in setting time with increase in cementitious additions and with increase in superplasticizer dosage. The higher percentage substitution of cement with silica fume and alccofine resulted in decrease in compressive strength due to the simultaneous acceleratory and retarding effects of cementitious additions and the superplasticizer. The results of the rheological measurements revealed that silica fume possess greater elasticity than that of the alccofine which possess greater yield stress and plastic viscosity.