- Cite article

- Download PDF

- Share article

- 5 Downloads

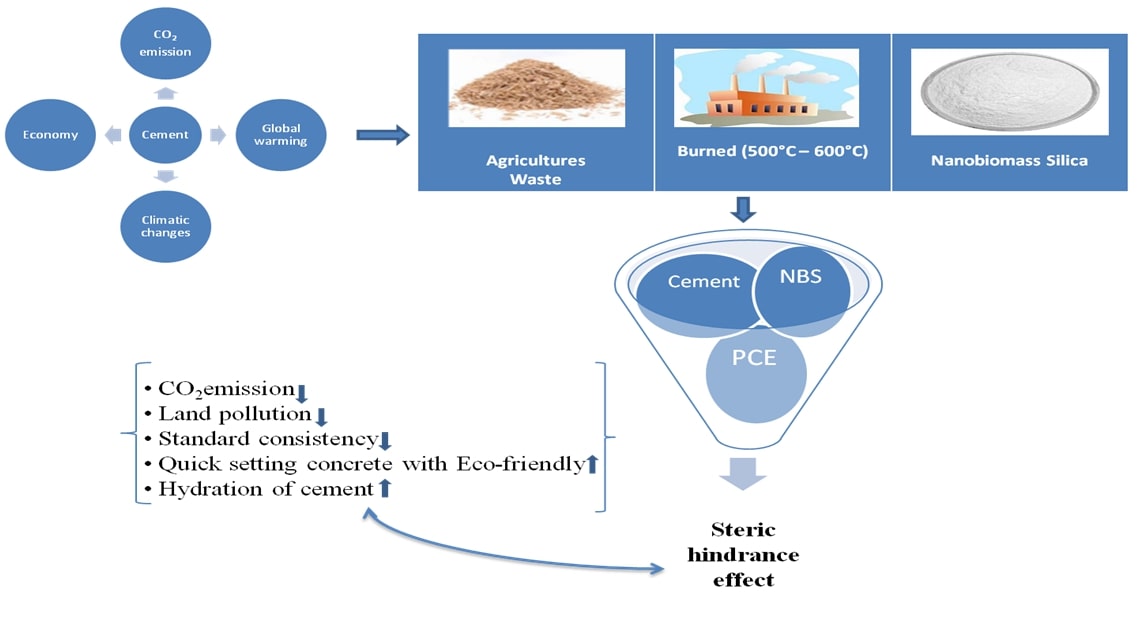

Pozzolanic material and a chemical admixture have been used in the current investigation; Nano Biomass Silica (NBS) and Poly-Carboxylate Ether (PCE). NBS produces 20% of the 590 million tonnes of paddy produced globally. Amorphous silica, a mineral component used in concrete, is present in sizable levels in these by-products (NBS). A binary and ternary of NBS with partial replacement of Ordinary Portland Cement (OPC) and the addition of PCE with varying dosage by weight of cement were used. This study's goal is to determine how they affect paste Setting time (ST) and Standard consistency (SC), and hydration temperature evaluation conducted in hot weather with various percentage at NBS from 6, 12 and 18% and PCE with varying dosage from 0.8, 0.9 and 1%. The chemical bond & structure of pozzolanic and chemical admixture in the FTIR were analysed. While PCE showed very little impact on consistency, higher w/b ratios with higher NBS levels were required for the maintenance of OPC-NBS paste consistency standards. The Initial setting time (IST) & Final setting time (FST) for binary OPC-NBS pastes significantly raise to 6% NBS, followed by a decrease at 12% and 18% NBS. However, for OPC-PCE pastes, the IST increased to 0.8%PCE followed by decrease at 0.9% and 1% PCE. In cement paste, PCE can be added as an additive, but the FST increases with an increase in the PCE percentage. At the same time, the mineral admixtures NBS can be used as a cement paste to decrease the FST and also reduce agricultural waste. NBS will effectively use silica ash as a microstructure filler as an additive in manufacturing to produce a certain form of cement with specific IST and FST, in particular for the sustainability of building materials and in hot weather.