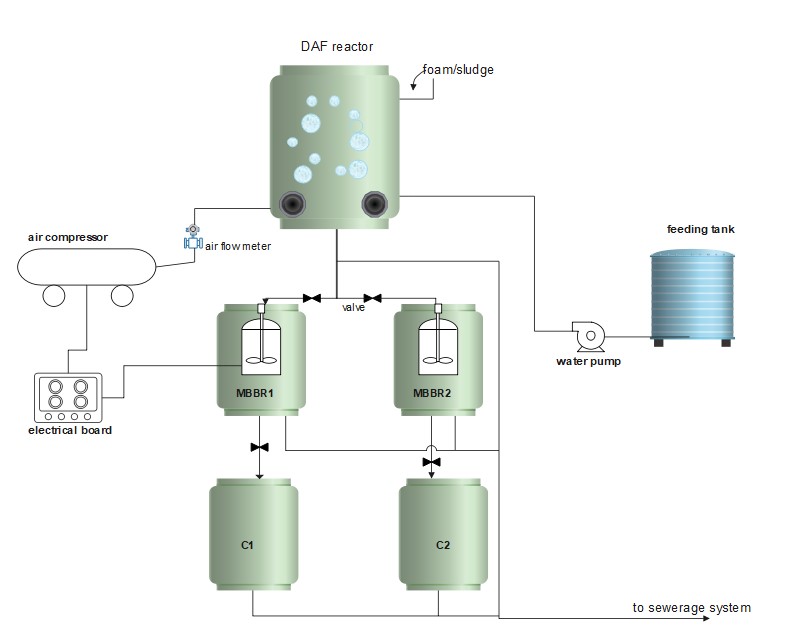

Numerous industrial processes, including petroleum refining, food production, car washes, leather manufacturing, and slaughter houses, generate significant volumes of wastewater due to their substantial water consumption during processing. The presence of oily wastewater has detrimental effects on surface and ground water resources, Human health and aquatic ecosystems. This study aims to integrate dissolved air flotation (DAF) and moving bed biofilm reactors (MBBR) for the treatment of oily wastewater. For this reason, a synthetic oily wastewater was prepared by utilizing commercially available powdered starch as an organic source, along with diesel oil and a finely ground soil. In addition, the experiments were designed and analyzed using Response Surface Methodology (RSM). DAF reactor factors were flotation time and air flow rate. While the MBBR reactor variables were mixing time and hydraulic retention time (HRT). The responses were chemical oxygen demand (COD), oil and grease(O&G), ammonia (NH3-N) and total suspended solids (TSS). Optimum results obtained by RSM for the DAF were 10 min for the flotation time and air flow rate of 72 L/min. in addition, HRT for both MBBRs was 23.5 hr and mixing time of 13 min and 23 min for MBBR1 and MBBR2 respectively.

Total file downloads: 19