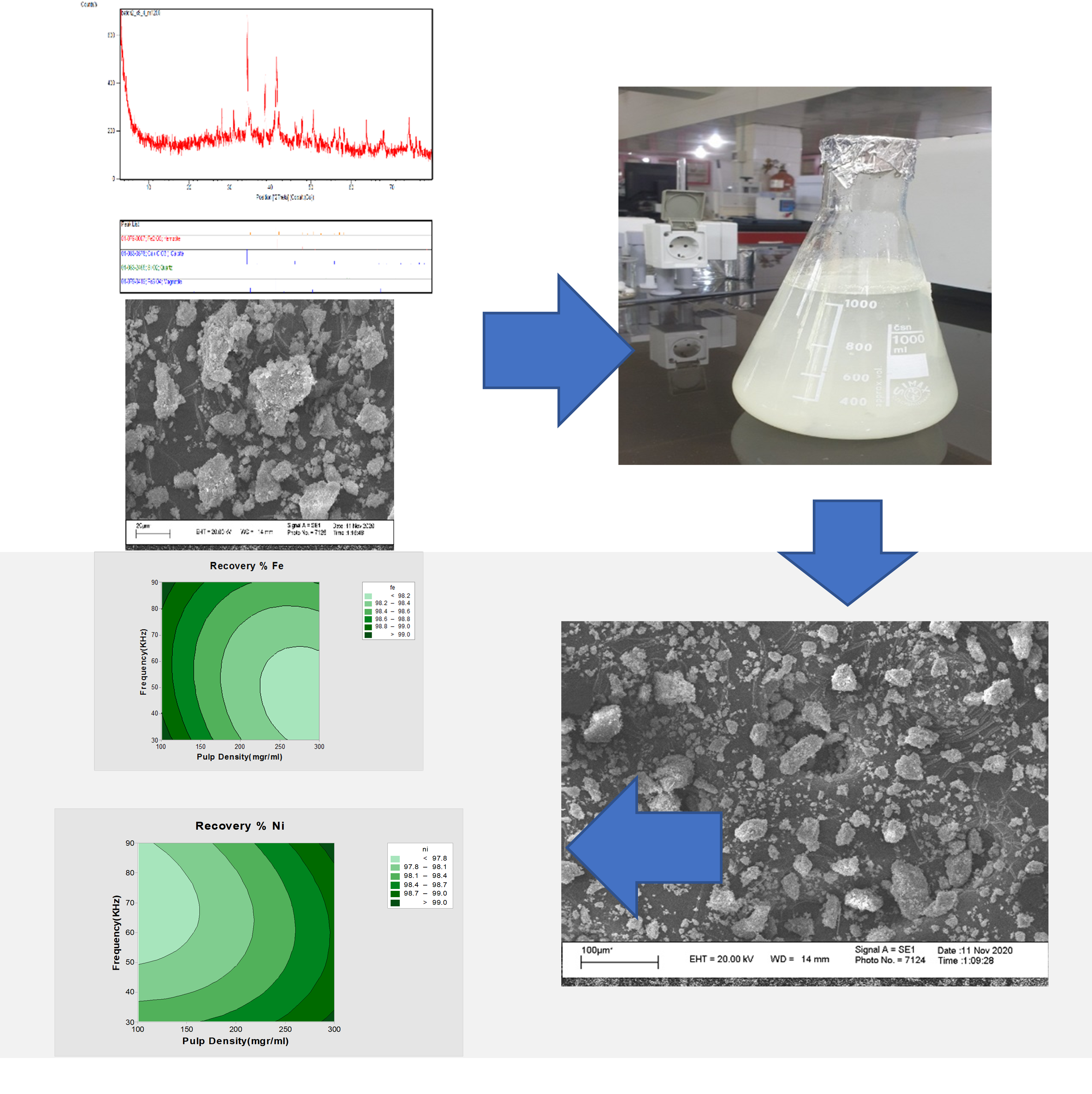

This study assessed the efficiency of Fe, Al, Ni and Sr removal from the steel sludge using the coupled bioleaching with Thiobacillus thiooxidans and ultrasonic waves. Growth conditions were optimized using the surface response method. The bacterium was adapted successively to three heavy metal-containing solutions with different concentrations of 100, 200, and 300 mg/ml. Samples were exposed to ultrasonic waves at frequencies of 30, 60 and 90 kHz and durations of 20, 30 and 40 min for two weeks. The highest Fe removal efficiency of 98.45% was obtained using the T. thiooxidation, wave frequency of 30 kHz for 40 min, and pulp density of 100 mg/ml. The maximum removal efficiency was found to be 99.74% for Al under a wave frequency of 90 kHz for 20 min and a pulp density of 300 mg/ml, approximately 100% for Ni under a wave frequency of 30 kHz for 20 min and a pulp density of 300 mg/ml, and 98.45% for Sr under a wave frequency of 90 kHz for 20 min and a pulp density of 300 mg/mL. Results showed that the removal efficiency of Ni and Al bioleaching improved significantly (P <0.05) under the ultrasonic irradiation while the removal efficiency of Fe and Sr remained statistically unchanged (P> 0.05) with and without the application of ultrasonic waves.

Total file downloads: 8