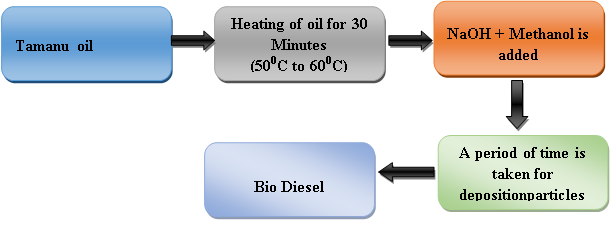

Diesel engines cause major pollutants such as hydrocarbons (HC), carbon monoxide (CO), and oxides of nitrogen (NOx). These emissions affect environmental systems and lead to global warming and climatic change effects. These pollutants also affect humans and lead to health problems like lung cancer, breathing problems, and headaches, etc. Hence, some necessary action has to be taken to minimise these pollutants. There are several steps available to control these emissions. The coating of the piston using catalytic material is an effective method and novel approach of reducing emissions in diesel engines with alternate fuel operated diesel engines. The copper-chromium-zirconium alloy (CuCr1Zr) is known for its good thermal conductivity and good catalyst material, and the piston is coated bycopper-chromium-zirconium alloy with 250µm thickness. Tamanu oil was blended with diesel fuel in a 20% (B20) to 40% (B40) ratio and used as an alternate fuel for the coated engine. The results showed a significant reduction in emissions and improvements in performance. In this research, the Taguchi with grey relational analysis (GRA) optimization technique is also used to study the effect of engine operating parameters on the emission level such as load and fuel for copper-chromium-zirconium alloy-coated diesel engine. Based on experimental results found that fuel is the most influential factor for CO and HCexhaust gas emissions reductions for coated type diesel engines.

Total file downloads: 3