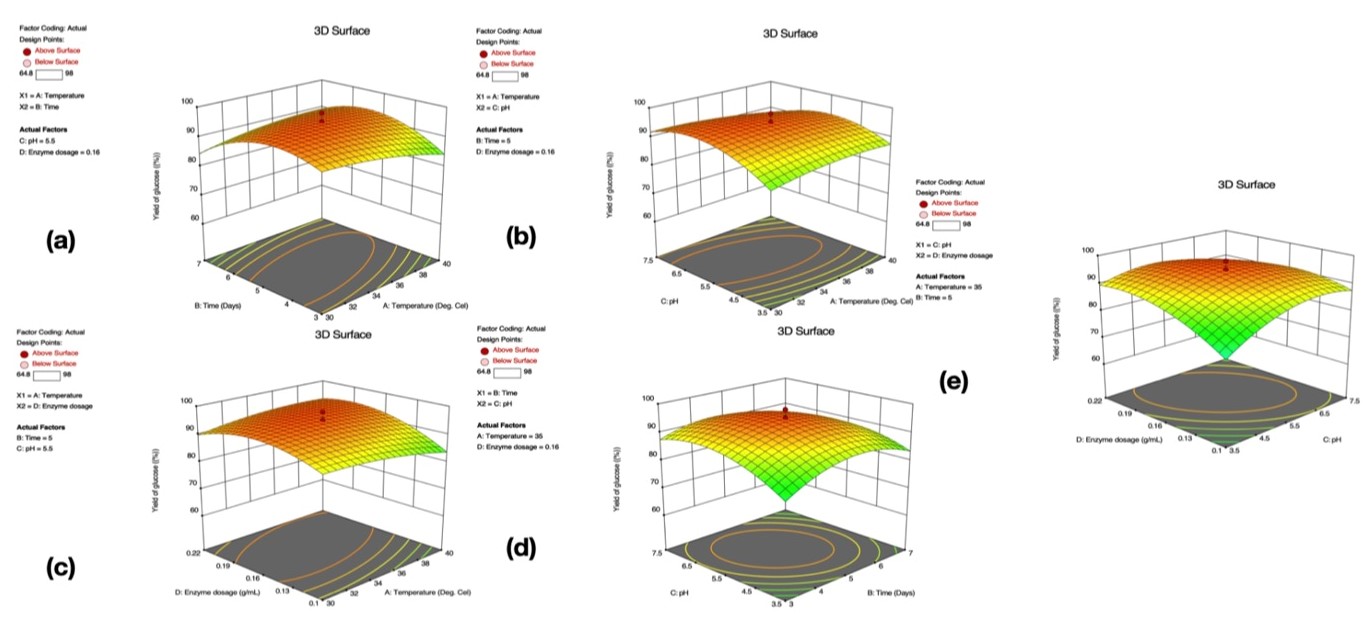

The enzymatic fermentation of starch from non-edible sources using Aspergillus niger could help supplement the increasing glucose demand within the Nigeria food supply chain. Also, response surface methodology could help optimise the glucose production of starch hydrolysed from cocoyam tubers. In this work, we evaluated and optimized the enzymatic-fermented glucose production of wild cocoyam starch using response surface methodology. Wild cocoyam starch was hydrolyzed using A. niger isolated from the soil. The optimization process involved temperature, time, pH, and enzyme dosage, alongside the kinetics and thermodynamics of enzymatic hydrolysis. Optimum conditions for glucose yield of 95 % by enzyme hydrolysis included: temperature = 35 °C; time = 5 days; pH = 5.5; and enzyme dosage =0.16 g/mL, with wild cocoyam showing promising as substrate. The F-value of quadratic model terms appeared statistically significant (F= 65.42, p<0.0001). Fourier Transform Infra-Red Spectrometer (FTIR) and Gas Chromatography-Mass Spectrophotometer (GC-MS) analyses confirmed characteristic bands of glucose as industrially promising with 60% purity. Further, the enzymatic hydrolysis adhered to Michaelis-Menten kinetic model with maximum reaction rate of 82.6 ml/day at 35 °C.

Total file downloads: 4