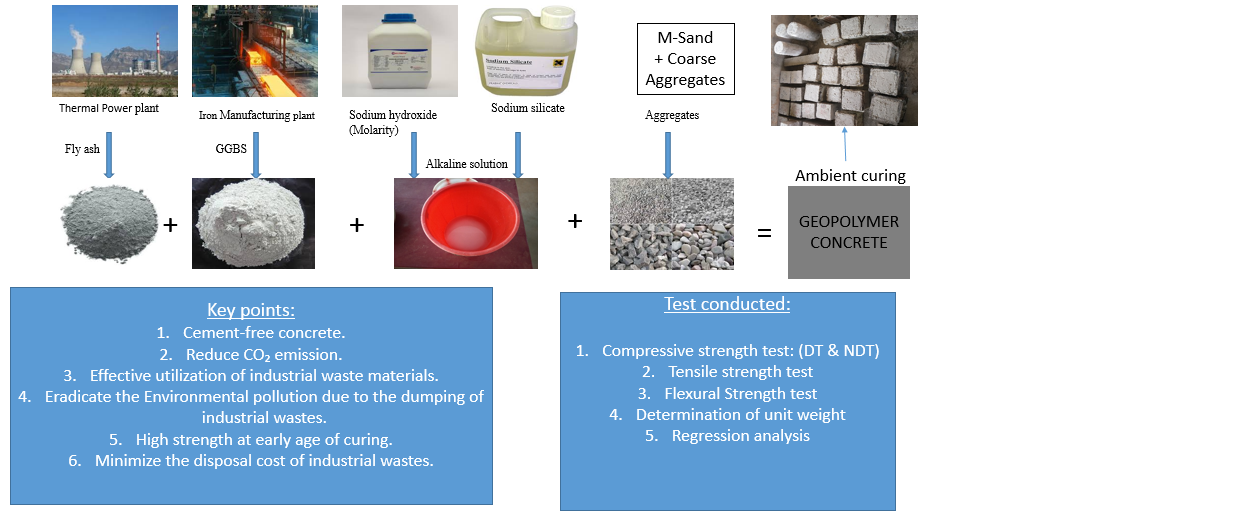

Nowadays, the increase in population and industrial growth that generates lot of waste products which creates disposal problems and severe environmental hazards. The cement industry is one of the important sectors which liberates greenhouse gas such as carbon dioxide. The consumption of waste products which eradicate the disposal issues and also it diminishes the emission of greenhouse gases to the environment. This is an important reason for the introduction of cement-free Geopolymer Concrete. This paper was invented to understand the suitability of Geopolymer Concrete cured at ambient temperature in the construction industry and the effect of molarity on strength properties. Totally, five types of Geopolymer Concrete mixes were prepared by altering the molarities of sodium hydroxide like 4M, 6M, 8M, 10M and 12M. The compressive strengths (1, 3, 7, 14 and 28 days), splitting tensile strengths (7, 14 and 28 days) and flexural strengths at 28 days were studied for aforesaid molarities. Generally, the rise in molarity increases the compressive strength. The ultimate strength was achieved up to 57.53MPa at 28 days for 8M Geopolymer Concrete. For the validation of compressive strength predicted by Destructive test (DT), the Non-Destructive tests (NDT) (Rebound Hammer and Ultrasonic pulse velocity) were carried out at resembled age of curing. Regression analysis is also done between compressive strength established by DT and NDT results. The arrived linear regression equations were well correlated with the experimental results and the co-efficient (R2) values varied from 0.8970-0.9967.

Total file downloads: 12