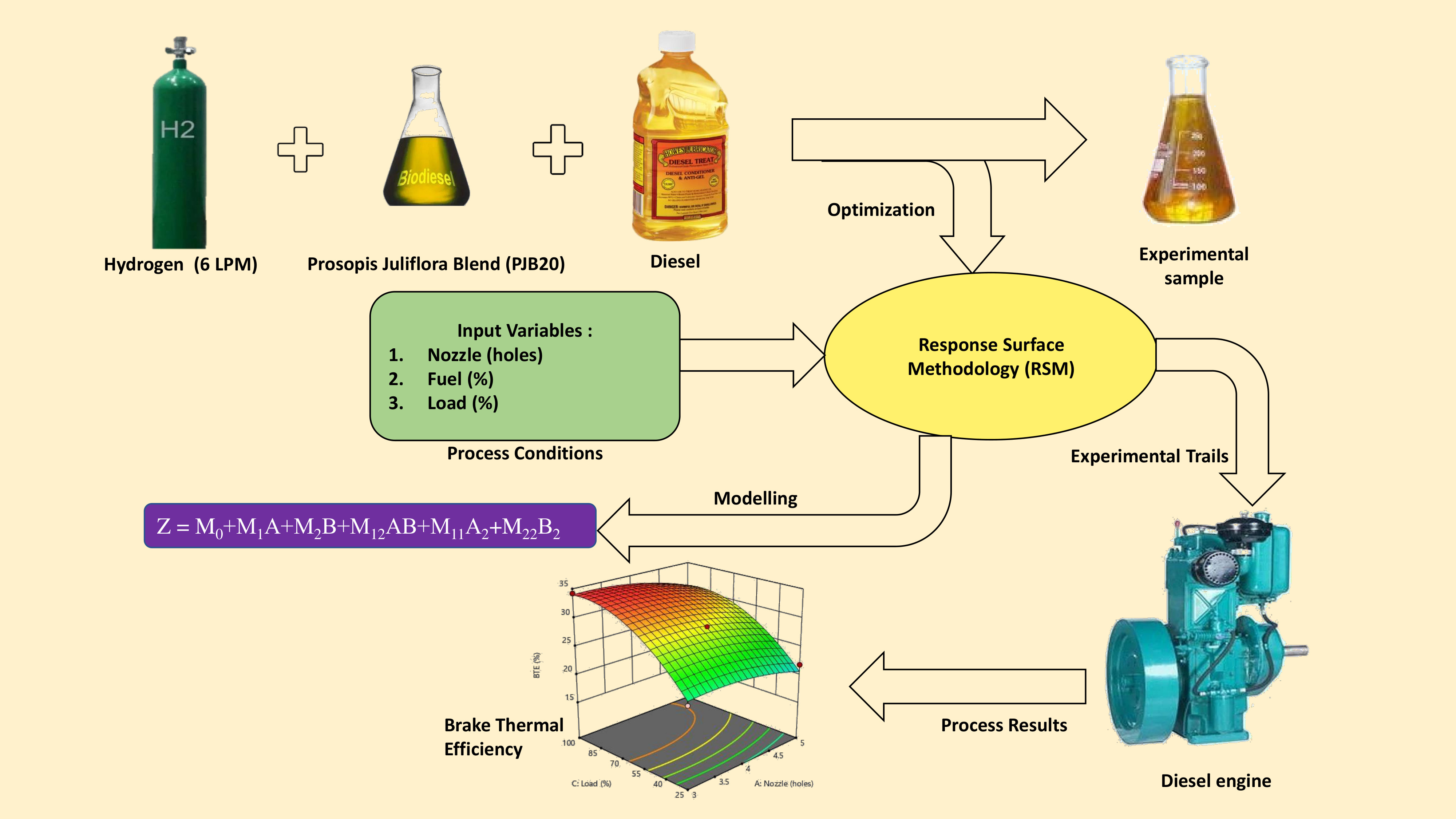

Hydrogen is a possible future energy carrier due to its production potential from renewable resources and compatibility with existing diesel engines with minor changes in dual-fuel mode. Various studies have explored modifying engine structure, optimizing operating conditions, adjusting engine parameters, and using exhaust gas catalysts to safely and efficiently integrate hydrogen and other gaseous fuels. This study examines the improvement and emission phenomenon of Homogeneous Charge Compression Ignition (HCCI) engines using diesel, biodiesel, and a blend of Juliflora Biodiesel (B20) with hydrogen at 6 LPM in dual-fuel combinations. The HCCI engine's versatility in utilizing diverse fuels, including hydrogen, biofuels, diesel, and gasoline, is a significant advantage. In contrast, injector nozzle number is limited in research, particularly in gaseous fuel. This study employs gaseous fuel to evaluate how nozzle holes impact engine performance and emissions. The objective of this research is to experiment with an HCCI engine in dual-fuel mode by varying the injector nozzle holes (3, 4, and 5) to identify the optimal fuel mix and operating conditions that enhance performance and reduce emissions. Our primary fuel was Prosopis Juliflora Biodiesel (B20) with hydrogen use as a secondary fuel introduced through the inlet manifold. The experimental results indicated that a 4-hole nozzle at 50% load (B20 + H2 @ 6 LPM) provided superior atomization and increased brake thermal efficiency, along with reduced HC, CO, and smoke opacity compared to the 3 hole and 5 hole nozzles. Response surface methodology confirmed that these experimental findings align with optimized parameters. Therefore, we recommend using a 4-hole nozzle for the B20 + H2 blend at 6 LPM and 50% load to achieve enhanced performance and emission reductions in HCCI engines compared to 3-hole and 5-hole nozzles.

Key words: Hydrogen blending, Injector nozzle, optimization, Response Surface Methodology (RSM), Engine efficiency, Emission control

Total file downloads: 30