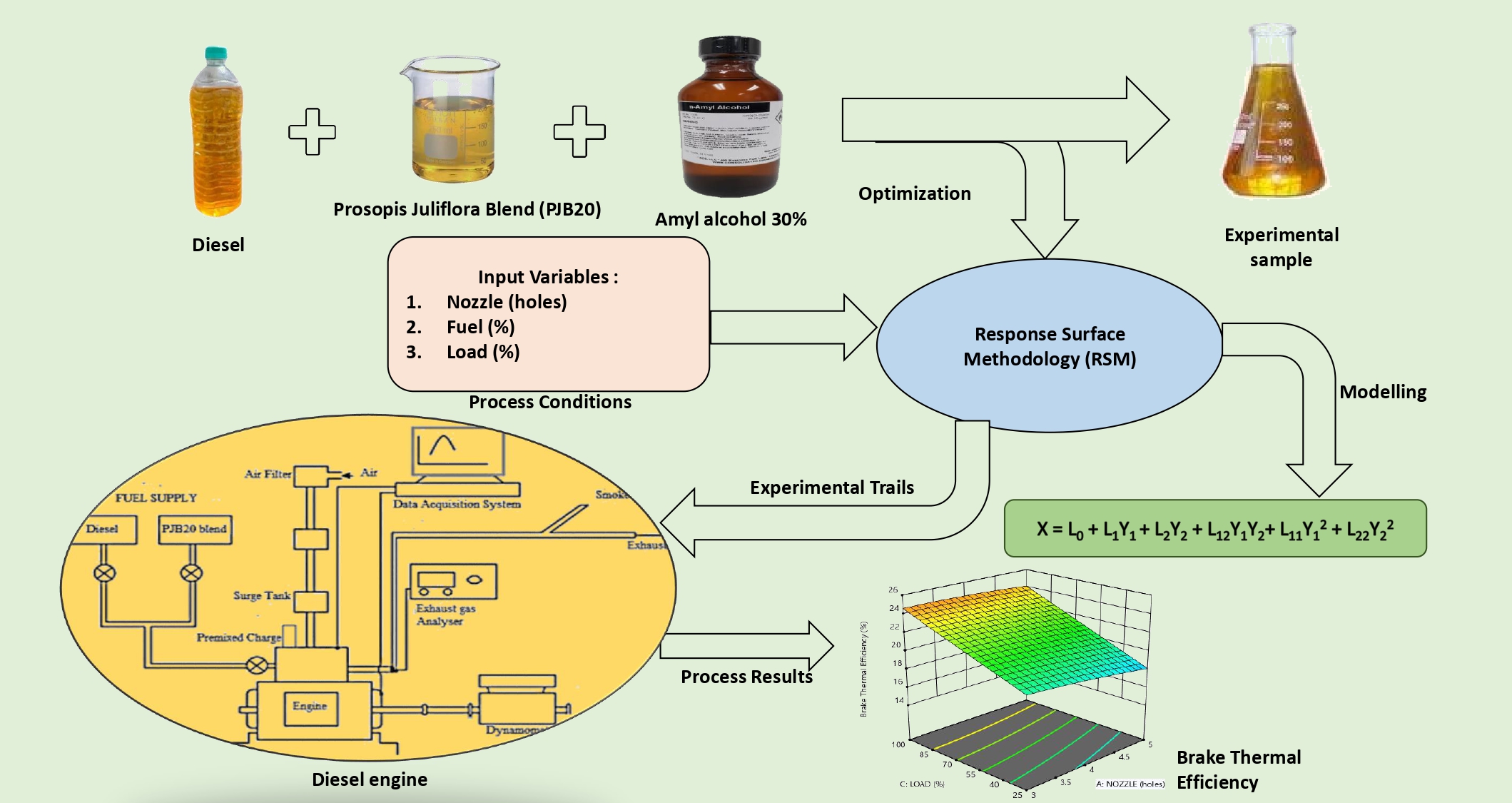

Injector nozzle hole design is vital for enhancing sustainability by improving engine performance and reducing emissions. The study aims to investigate the impact of altering the number of nozzle holes (3, 4, and 5) on the performance of diesel, prosopis juliflora biodiesel (PJB20), and a blend of PJB20 with amyl alcohol in dual fuel mode. For optimization of engine, response surface methodology was used with the input parameters of load (25, 50, and 100%), nozzle hole (3, 4, and 5), and fuel blends (Diesel, PJB20, and PJB20-amyl alcohol) whereas the output response of Brake thermal efficiency (BTE) and Nitrous oxide (NOx) are taken as factors. The Derringer Desirability technique was used to optimize central composite design. Utilizing PJB20-amyl alcohol 30% through a 4-hole nozzle increased BTE by 3.30% and 8.32% in comparison to three-hole and five-hole nozzles. The nozzle holes were 23.1, 23.89, and 21.9% compared to 25.95% for neat diesel. Additionally, the NOx levels were 883, 1062, and 940 ppm compared to 1405 ppm for neat diesel operation with a 3-hole nozzle. PJB20 -30% amyl alcohol blend produced less, CO and HC while NOx emissions enhanced while comparing with diesel and PJB20. The optimized specifications of the dual fuel resulted in maximum performance and minimum emissions found at a four-hole nozzle, a fuel blend of 27.40%, and an 86% load. It was determined that the predicted responses for BTE and NOx were 24.84% and 1056.7 ppm respectively. Finally, the numerical and experimental data indicate that the 4 hole mixture of PJB20 - 30% amyl alcohol produces maximum engine efficiency and minimum emissions, that are optimized.

Total file downloads: 63