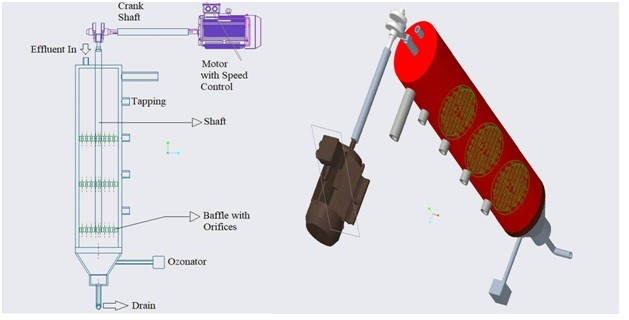

Treatment of tannery effluent is a key issue that requires novel research. The presented work is an attempt to carry out advanced oxidation process in a Multi-orifice Oscillatory Baffled Column using ozone as oxidizer and compare the extent of treatment with sono-catalytic treatment with TiO2 as catalyst. Studies have been carried out to understand the effect of treatment time, concentration of effluent and oscillation frequency upon ozonation and the effect of power of ultrasound, time of treatment and catalyst loading for sono-catalytic treatment. For ozonation the COD, BOD and TDS reduction obtained are 88.8%, 84.01%, 90.73% respectively and for sono-TiO2 treatment the reduction of COD, BOD and TDS obtained are 91.2%, 91.5%, 94%. Optimization and analysis of variables is carried out to identify the effective factors for treatment.

Total file downloads: 12