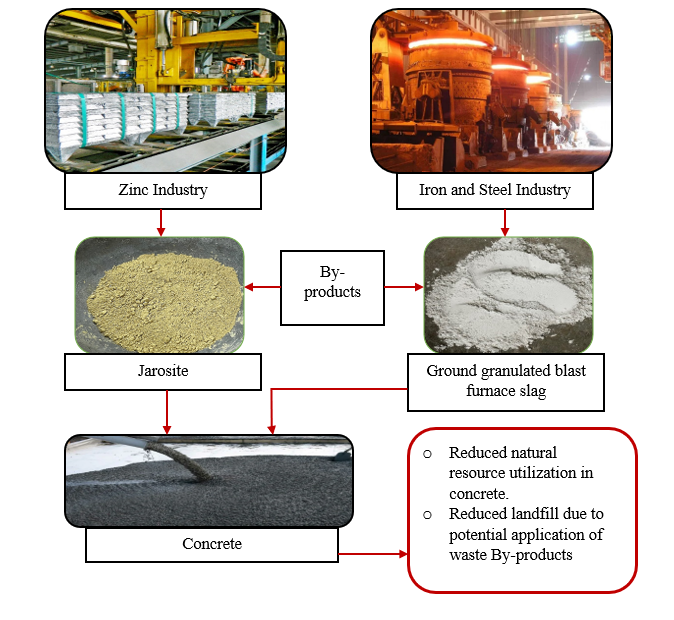

The rapid growth of infrastructure leads to industrial waste accumulation and natural resource depletion, raising the need for sustainable solutions. When zinc is refined, a significant amount of non-biodegradable material called jarosite (JS) is generated, requiring proper environmentally friendly disposal techniques. The present study investigates ternary blended of Portland cement with partial replacement of 20% ground granulated blast furnace slag and jarosite at (5 – 25%) as a binder material to develop a sustainable concrete mix. To comprehend the effectiveness of jarosite-GGBS blends in concrete experimental research is performed to investigate the mechanical properties of ternary blended concrete. Additionally, SEM and XRD analysis were used to observe the microstructure and chemical phases of the developed concrete. From the experimental investigations, it is perceived that the incorporation of jarosite-GGBS blended concrete provided an increase in strength properties for all the mix proportions. The microstructure study shows a decrease in voids and the formation of sufficient CSH gel, justifying improved mechanical properties. The maximum increase in compressive strength of 50.93% is observed for the 10% replacement of the level of jarosite in the concrete mix. The overall research findings provide insight into the functionality of GGBS and jarosite blended concrete and the potential of jarosite as a sustainable, reusable industrial waste material.

Total file downloads: 12