- Cite article

- Download PDF

- Share article

- 12 Downloads

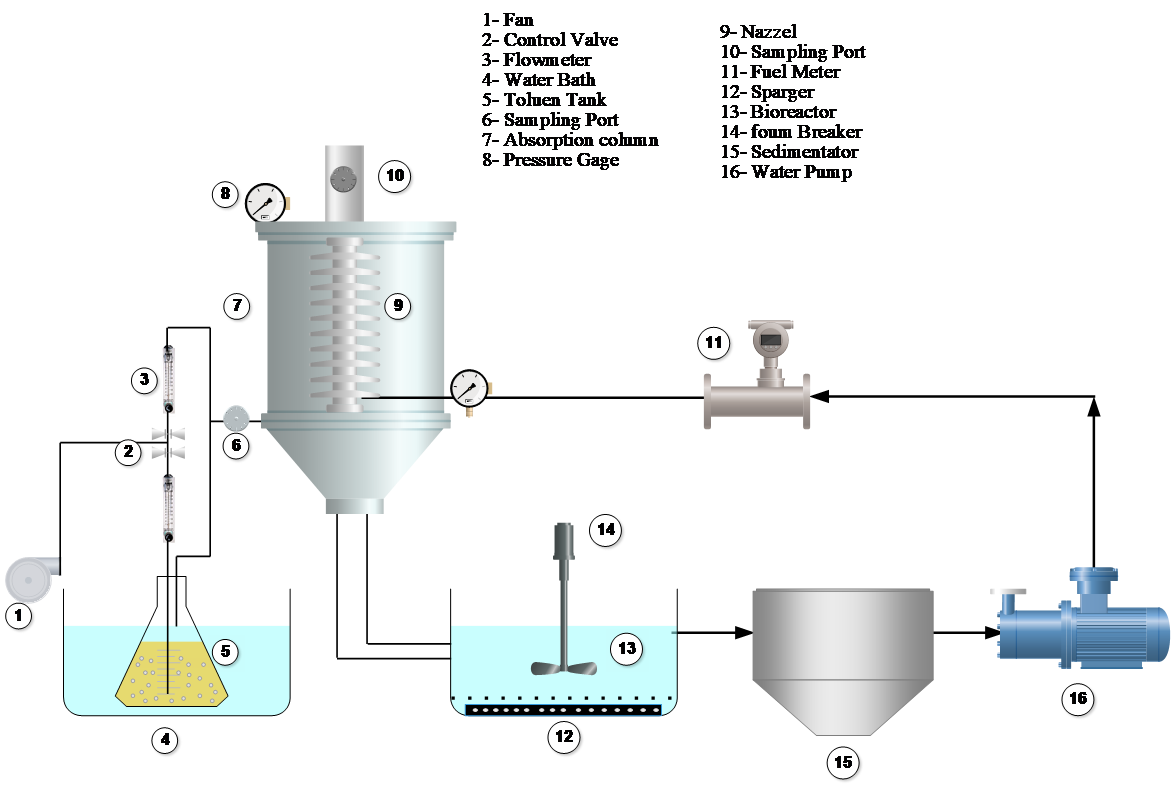

Toluene is a monocyclic aromatic compound that finds widespread use in various industrial processes. Due to its harmful effects on human health and environment, this study aimed to remove toluene from the air stream using a two-phase bioscrubber. The bioscrubber design consisted of an absorption column that separated contaminants from the gaseous phase to the aqueous phase and a bioreactor for the biodegradation of toluene by microorganisms. Organic phases of cutting oil were added at concentrations of 5%, 7.5%, and 10%. The biodegradability test results revealed that 98% of the toluene concentration was further biodegraded after 72 hours compared to the control sample. The results showed that the use of 5% concentration of cutting oil increased the efficiency from 22% to 55%, At a concentration of 7.5%, the lowest efficiency was 38% and the highest was 63%. Also, the minimum and maximum removal capacity are 17 and 269 g/m3.h, respectively. Efficiency at a concentration level of 5% of cutting oil as an organic phase is better than a concentration of 7.5%. These findings indicate that the efficacy of the bioscrubber is better when using a 5% concentration of cutting oil as an organic phase. Moreover, this study is the first to use cutting oil as an organic phase in Iran, which showed that using cutting oil in concentrations less than 10% had no adverse effects on microorganisms' growth.