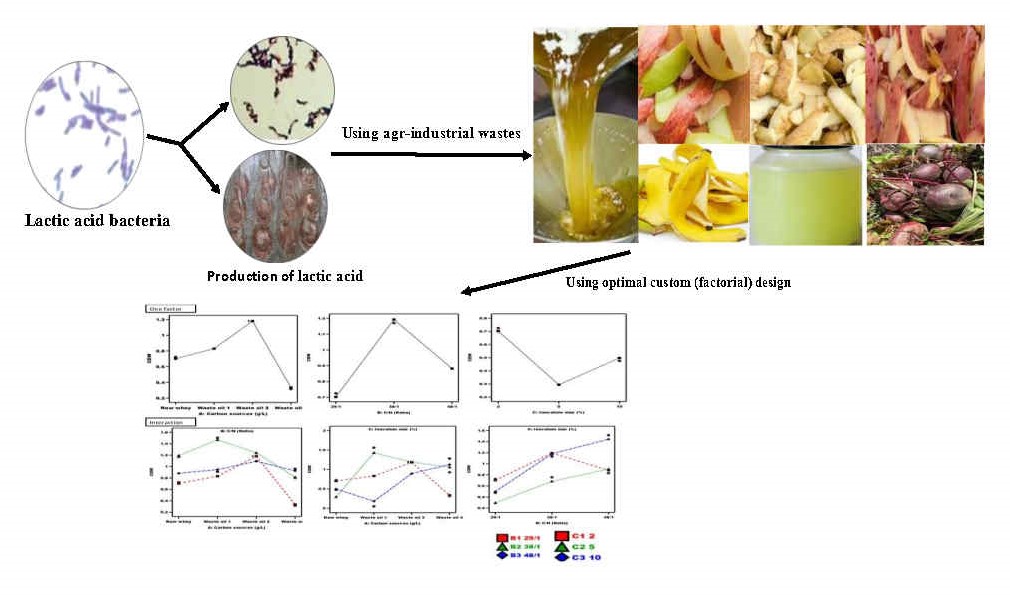

Bioplastics made from renewable resources, such as contemporary biomass, have been developed more quickly as a result of global pollution from plastics made from petroleum, but it is still unclear how these materials will affect ecosystems. A common biopolymer that will make up 33% of the bioplastics produced in 2021 is polylactic acid (PLA). Forty-two bacterial isolates (soil, food wastes, and water wastes) were obtained, and 8 lactic acid bacteria were used for lactic acid (LA) production. These bacteria were classified into three categories, namely high, moderate and low LA producing bacteria which gave LA concentrations ranged from >1.0 g/L (3 bacteria), 0.5 to 1.0 g/L (21 bacteria) and 0.1 to 0.5 g/L (26 bacteria), respectively. The Sudan black staining method revealed that 16 bacteria out of 50 were capable of storing PLA granules, with three lactic acid bacteria referred to as Lactococcus thermophilus, Lactobacillus rhamenose, and Lactobacillus retrieria being the most efficient. The sodium dodecyl sulphate procedure was used to extract PLA from the selected LAB, and the results revealed that L. rhamnose was the most effective strain for producing both lactic acid and PLA. The most important fermentation parameters for lactic acid and polylactate polymer production were evaluated using an optimal custom (factorial) design. The interaction between three factors of selected potato oil waste, C/N ratio (48/1), and inoculum size (10%) resulted in an increase in lactic acid and polylactate polymer productivity by L. rhamenose L6, which reached 0.85 g/L, 0.96 g/L, and cell dry weight 2.33g/L, respectively.

Total file downloads: 32