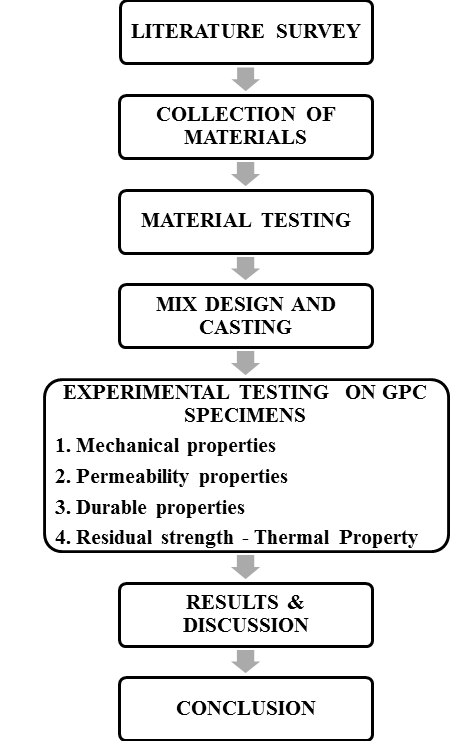

Permanent damages and spalling occur in conventional concrete due to high temperatures. Also concrete loses its compressive strength amounting to about 50 to 75% of the original strength as reported in most of the research works. As opting for high grade of concrete leads to higher costs and emits CO2, an attempt to develop thermal-resistant geopolymer concrete is done. A new class of silica-alumina binders called geopolymers has the ability to withstand high temperatures. Generally geopolymer concrete (GPC) is having good strength and durability properties. In this paper, the heat resistance and strength performance of geopolymer is improved by adding aluminium oxide as an admixture in the doses of 1% and 2% by weight of rice husk ash. With rice husk ash, fine aggregate and coarse aggregate, thermally resistant GPC was created. As alkali activators, sodium hydroxide and silicate were employed. The molarity of NaOH solution was 12 and 14. The specimens were cast and oven-cured at 60°C for 24 hours. The specimens were tested to determine the strength, permeability, durability and thermal studies of geopolymer concrete.

Total file downloads: 12