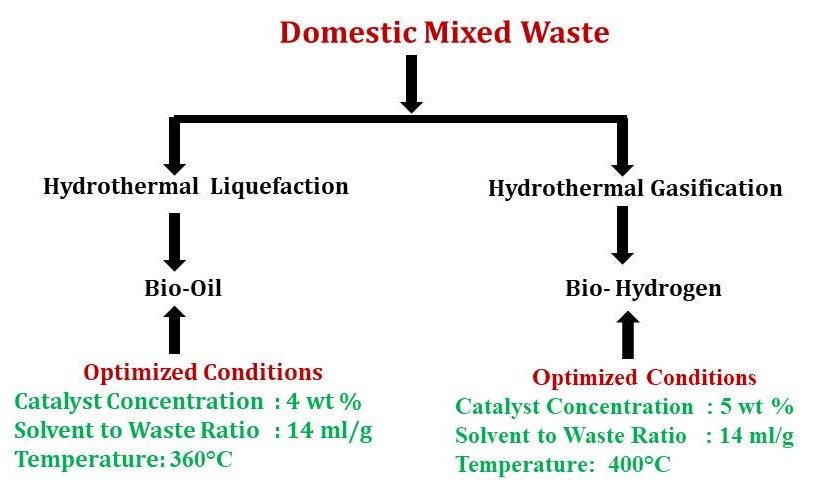

This research focuses on hydrothermal gasification (HTG) and hydrothermal liquefaction (HTL) studies to produce bio-hydrogen from domestic mixed waste. HTG and HTL studies were studied at temperatures of 300–450°C and 300–400°C, correspondingly, with a catalyst level of 6 wt %. The sol-gel technique was used to make the Bentonite/Nb-TiO2 catalyst. For a solvent-waste proportion of 14 millilitre/gram, an C2H5OH - water proportions of 2:2, and a period of one-hour, maximum H2 output from HTL was 30 wt % (catalyst loads: 4 wt %) and HTG was 40 wt % (catalyst loads: 5 wt %). As C2H5OH acts as half-solvent and ideal solvent to bio-mass capacity it shot up H2 result in the HTG procedure by methanation, gas water shift and improving responses in the organization. The second output of the HTL procedure was bio-oil, which yielded 35 wt % with O/C as well as H/C standards of 1.2 and 1.0, respectively, and an HHV of 42 Mega Joule/kilogram. In the HTL system, mechanistic procedures such depolymerization, hydration, reduction, and hydrolysis generated in a larger proportion of gaseous product. Thermal and the solvent-to-waste proportion is the ideal factors in the H2 synthesis procedure, according to experimental analysis. Energy nexuses from domestic mixed trash are taken over in this research.

Total file downloads: 1