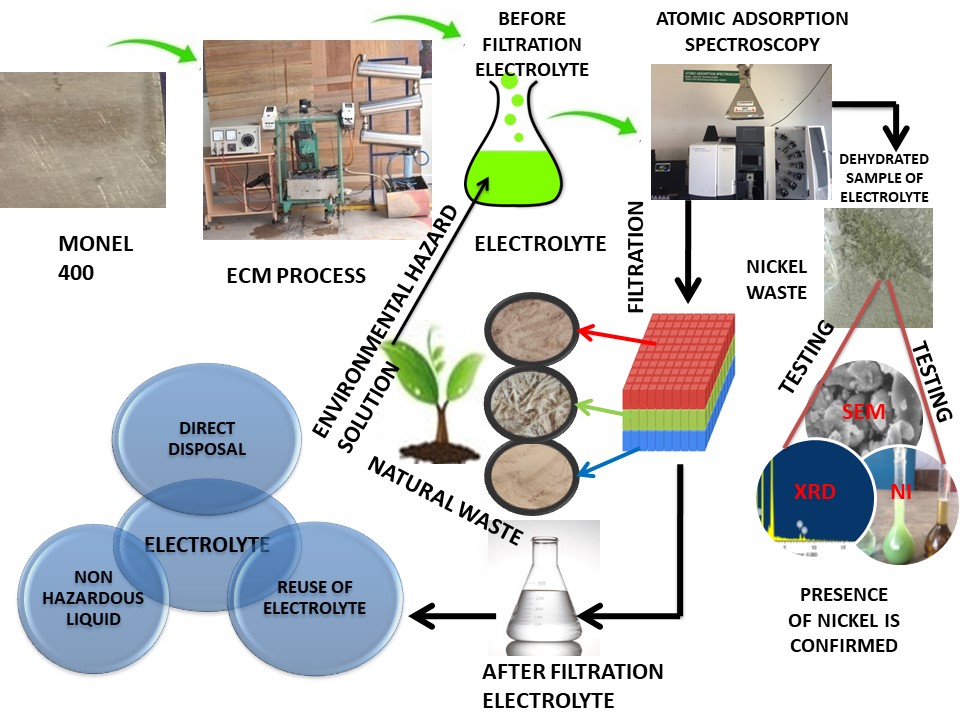

Electrochemical Machiningplayed a vital role in the aircraft, atomic, and healthcare industries via electrochemical machining (ECM). Even with difficult-to-machine materials. ECM has generally preferred to machine Nickel-based alloys compared to other non-conventional and conventional machining tools. During machining with ECM, the Nickel-based alloys discharge toxic nickel hydroxides in sludge, which is very harmful to the environment. Therefore, in this work, investigations have been made to analyze the amount of nickel content discharges into the electrolyte and develop an eco-friendly filtering mechanism for nickel discharges to attain sustainable manufacturing. Bio-degradable coconut shell powder and wood dust powder were used in the filtration setup to filter the sludge. Thus, Eco-Friendly Electrochemical Machining (EECM) was developed and investigated the machining on Monel 400 alloys. Measurements including applied voltage (V), flow rate (U), and electrolyte concentration were commonly used to compare the amount of material removalrate (MRR) and the amount of nickel in the electrolyte before and after filtering. The contour plots were designed to show the impact of cycle boundaries on nickel particle releases and their collaboration. Researchers found that natural environmental debris, including coconut shell powder, wood dust powder, and bagasse, were excellent at filtering out nickel levels from the electrolyte.

Total file downloads: 2