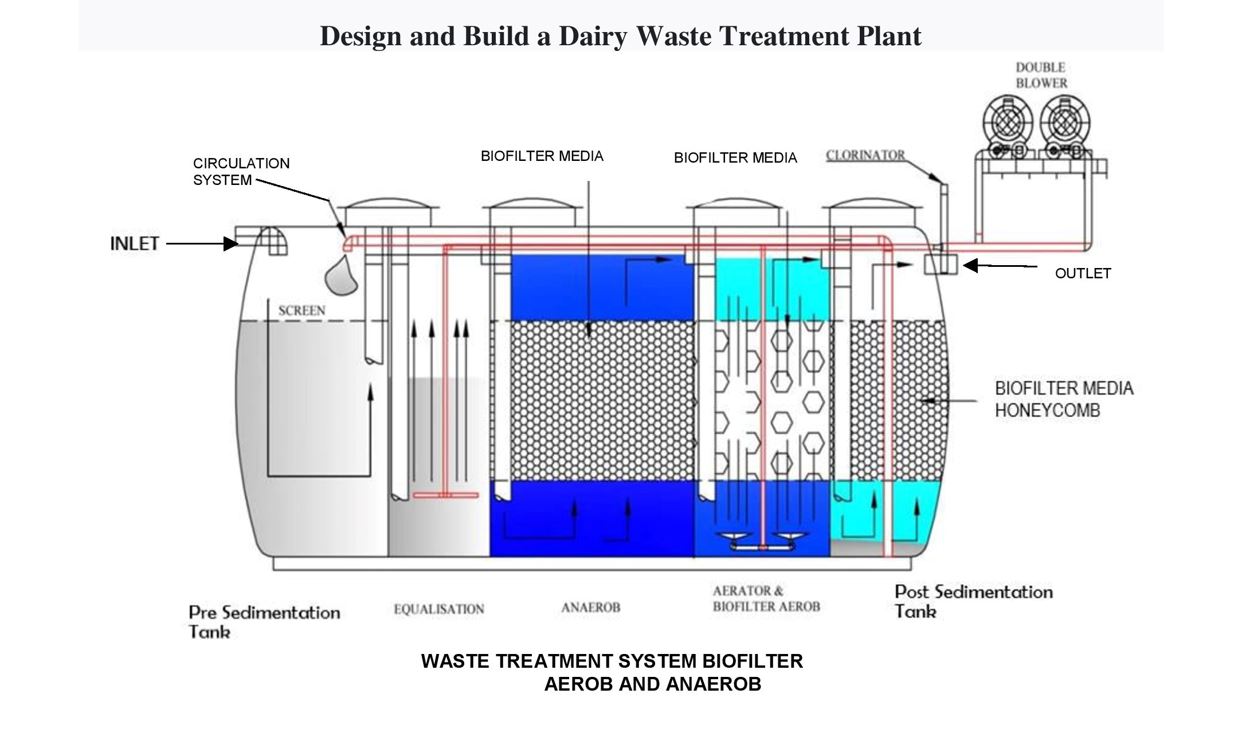

The dairy industry is one of the industries that continues to grow in Indonesia in line with the large demand for dairy foods. Liquid waste originating from the dairy industry has a special character, namely susceptibility to bacteria. This waste is very easy to decompose and if it is not immediately recycled or controlled it will be very dangerous to the environment around the factory. This research was carried out through the following stages: the seeding process for 12 days, as a stage of the process of bacterial growth and development, marked by a neutral pH, which ranges from 6.9 to 7.All wastewater originating from the production process is channeled into the initial reservoir that has been lye is added which functions to neutralize waste oil. The filtered water enters the aerobic tank, which functions to reduce pollutants in the form of BOD, COD, TSS, Oil and Fat, NH3N, and pH by breaking down bacteria without the need for oxygen. The next stage is that the waste is channeled into an aerobic tank made in the form of a honeycomb which is designed to adhere to the valley-breaking bacterial biofilm for the growth of bacteria. This media is also called wasp nest biofilter media. The percentage of reduction in BOD, COD, pH, NH3N, Oil and Fat before and after being filtered through the milk waste filtering installation at KPSBU Lembang, West Java. The results of the study were a decrease in BOD, 86.5%, COD: 86.83%, TSS: 78.2%, NH3N: 48.23% Fat and Oil: 91.9% and pH in the range 6-9.

Total file downloads: 18