- Cite article

- Download PDF

- Share article

- 32 Downloads

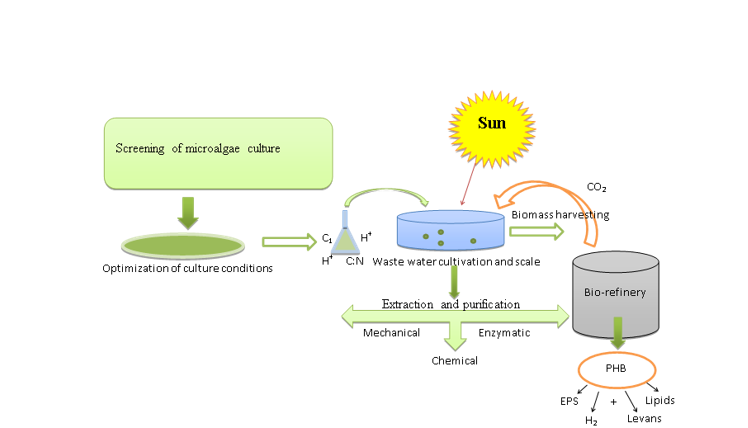

The global demand for plastic has risen, driven by plastic-based goods, exerting strain on the existing waste treatment infrastructure. Plastics typically consist of synthetic and semi-synthetic materials, mainly composed of polymers. Plastics include lightweight, cost-effective, easily manufacturable, flexible, and long-lasting characteristics, making them widely utilized by several individuals. Plastics consist of artificial polymers, including polyesters, polyurethanes, halogenated plastics, and acrylics. Plastics primarily impact the living environment of humans, wildlife, and numerous marine species. Plastic deterioration has a direct impact on human life via the drinking of tap water and an indirect effect through the consumption of animals. Plastic trash is categorized into main and secondary forms. Primary plastics were retrieved from their initial location and the deterioration of these primary plastics results in the formation of secondary plastics. Plastics are often categorized as micro, macro, and mega trash. The plastic particles range from 2 mm to 5 mm and are classified as micro trash. Mega debris refers to plastic particles with a dimension of 20 mm and are primarily utilized in food stores. Most individuals are concerned with diminishing the dependability of plastic items derived from fossil fuels, the primary catalyst for pollution in the worldwide ecosystem. About 8 million metric tonnes of plastic trash is disposed of annually in marine and terrestrial environments. Consequently, contemporary scientists are directing their efforts toward developing biodegradable plastics by utilizing various starch sources such as corn, potato, maize, wheat, and rice. We are now exploring alternative resources for producing Polyhydroxy butyrate (PHB), a type of biodegradable plastic that is sourced from food. To address this issue, we are gathering wastewater from the industrial sector, which is then utilized to generate Polyhydroxy butyrate [PHB] through the analysis of samples. To enhance the synthesis of PHB, many factors, including stress, pH, temperature, aeration duration, and agitation speed, were optimized. Hydroxy butyryl CoA, a precursor that undergoes polymerization to generate polyhydroxy butyrate (PHB), was utilized in this process. PHB exhibits insolubility in water and solubility in hydrolytic compounds. It demonstrates more excellent resistance to UV light but lesser resistance to acids and bases. It is non-toxic and readily dissolves in chloroform and other chlorinated hydrocarbons. The melting point of PHB is 175°C, and its glass transition temperature is 2°C. The tensile strength of PHB measures 40 MPa, which is comparable to that of polypropylene. Furthermore, PHB exhibits reduced stickiness when heated in comparison to other plastics. This study involved the synthesis of polyhydroxy butyrate from algae, which was then combined with natural polymers in varying ratios. The aim was to examine the resulting mix's physical, chemical, and mechanical characteristics and its degradation time. Upon evaluating the criteria, this technology has the potential for several commercial applications, including agriculture, medical, and the food business.