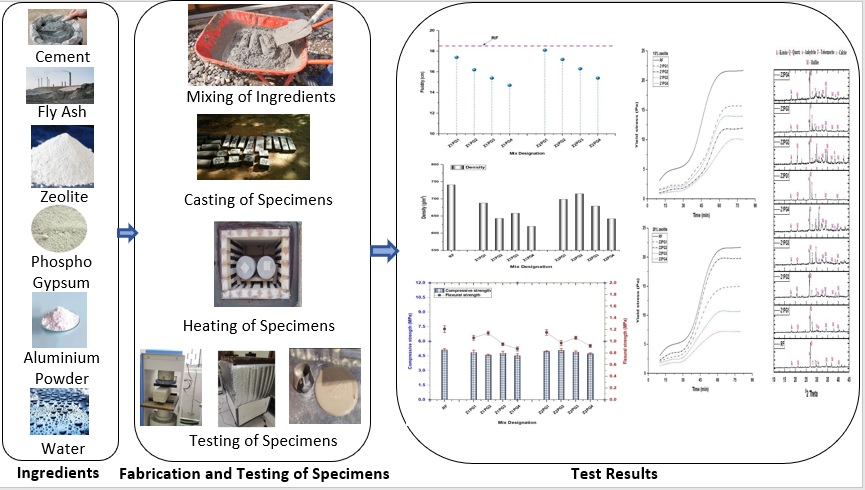

The feasibility of utilizing natural zeolite (NZ), phosphogypsum (PG), and aluminium (Al) powder (AP) as replacements for fly ash in autoclaved aerated concrete (AAC) is assessed in this research. This study examines the influence of NZ, PG and AP on AAC's fresh state properties, mechanical behavior, and thermal characteristics. Gas foaming properties were analyzed using X-ray diffraction (XRD) and Fourier Transform Infrared Spectroscopy (FTIR). Results show that natural zeolite and aluminum powder have acceptable foaming properties that contribute to AAC’s porosity and lightness when combined with phosphogypsum. The optimal dosage of PG, along with 10% and 20% zeolite and aluminum powder, enhances AAC performance through a synergistic effect. PG substitution for fly ash reduced density and increased the pH of the AAC slurry, affecting foam generation. Incorporation of PG potentially reduced workability due to its smaller particle size and larger surface area. Despite this, NZ, PG, and AP combinations resulted in AAC with satisfactory strength and flexural properties. AAC with phosphogypsum showed good strength, density, and thermal conductivity, though thermal conductivity was highest in control AAC. This study demonstrates these materials' potential to meet AAC’s construction requirements economically and efficiently dispose of phosphogypsum. Future research should explore other material combinations and their impacts on AAC, supporting sustainable construction and resource management.

Total file downloads: 35