You are here

Applicability of Membrane Reactor For Producing Environment Friendly Fuel Additive Glycerol Carbonate

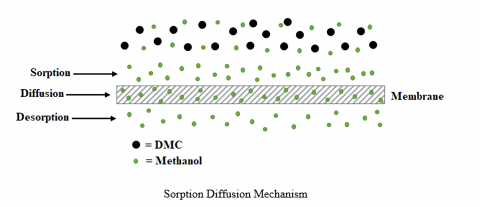

Production of glycerol carbonate (GLC) that is a fuel additive from green solvent dimethyl carbonate (DMC) and biodiesel by-product glycerin is environmentally friendly synthesis. The usage of waste glycerol from biodiesel plant makes the production cost lower. When the membrane aided technique is used for the production of GLC, this technique will be very promising technique. Because membrane applications are environment and energy friendly economical applications. The production with membrane aided can be made by catalytic membrane. In this study, catalytic membranes were developed from synthetic and natural materials to produce GLC by transesterification reaction between glycerol and DMC. The reaction gives methanol as byproduct. The catalytic membranes were used methanol retentive material for increasing the reaction conversion of glycerol to glycerol carbonate. The synthetic catalytic membrane materials were poly(vinylalcohol)(PVA), poly(vinylpyrrolidone) (PVP), Poly(4-vinylpyridine) (P4VP) polymers and CaO. The natural catalytic membrane material was chitosan biopolymer and waste eggshell. The properties of by-product methanol retentive of the polymeric membranes were determined from sorption tests. The tests were shown that the catalytic membranes would sorp by-product methanol during reaction. This pointed out that GLC synthesis can be made by membrane aided technique such as membrane reactor.